GW: What does it mean to you personally to be elected as FEVE President 2021–2023 following your initial spell in 2015–2017?

I am honoured that I get a second run at the Presidency during a crucial moment in glass packaging. I will be working very closely with FEVE members and the national associations, we have a great opportunity to capitalise on the societal trends towards health, well-being and sustainability – all of which strongly favour glass. We have the privilege to work with a material that has unique inherent sustainability benefits: it is endlessly recyclable and ensures quality and safety no matter how many times it is recycled. Glass is virtually inert and preserves the taste of the foods and beverages it protects. It adds prestige and the premium look and feel that supports our customers in nurturing their brands. And we are working towards glass as a climate-neutral and fully circular packaging.

GW: Following unprecedented conditions during the pandemic, how is the container glass industry currently performing in general in the European countries covered by FEVE members?

The industry is doing very well despite the pandemic. For many industries, 2020 was really challenging but since the food, beverage and pharma sectors are essential, the glass container industry supporting these sectors was classified as essential by extension. Our figures for 2020 are just out and sales were almost flat in units which is quite remarkable considering the environment. Our food and beverage container sales still remain above 2018 levels. In the flaçonnage sector, the Covid-19 pandemic had a diametrical effect on the different sectors. Pharmaceuticals increased by more than 4% in volumes (thanks to the glass vials for Covid vaccines) while cosmetics and perfumery fell strongly by 18% due largely to shut downs in the traditional retail channels for these products.

GW: How is the Furnace for the Future (F4F) initiative progressing?

First off, it is important to note that this is a project by a consortium of glass manufacturers; it is not a FEVE project. The consortium has applied for an EU grant under the Innovation Fund of the Emission Trading Directive; 311 projects were in competition; 70 were selected for the second phase of the selection procedure, and F4F is among them. The full application was submitted in June, and the Commission will take a final decision by November this year. Seven to 10 projects are expected to be selected at the end.

If the project is selected, the consortium will create a new legal entity to oversee the project (we work with 19 glass companies). Then the furnace will be built in 2022 and commercial bottles are expected to be produced by 2023.

The furnace has been conceived to demonstrate that melting glass with 80% electricity is feasible. A second generation may then go up to 100%. If successful, this concept then could be one of several options that glass container manufacturers have to reduce their carbon footprint.

Along the way, the consortium will work with furnace suppliers on further technology developments.

Last but not least, scalability also depends on sourcing enough renewable electricity at an affordable price. This is why we call on authorities to speed up the development of green power generation, but also to develop the necessary infrastructure to transport and deliver it where it is the most needed.

GW: Does FEVE have a policy for supporting other carbon reduction led initiatives such as the planned glass manufacturing pilot facility by Glass Futures or any of the collaborative hydrogen focused research programmes from other industry bodies?

F4F is a sectorial project grouping 19 different container glass companies, working together with FEVE on this hybrid technology. However, our members (individually or as part of other consortia) are also developing their own solutions and technologies. We are not directly involved as FEVE, but we follow these developments closely. The huge energy transition in front of us requires a multi-faceted answer. We need to explore the potential of electrification, but also hydrogen, biomass or other measures bringing us in the direction of carbon-neutrality. The situation and the framework can be very different from one country to another. It is therefore safer to have several solutions in the pocket to be able to adapt to each scenario and geographic situation.

GW: Since launching the ‘Close the Glass Loop’ action platform last year, what are the current priorities of this multi-stakeholder circular economy partnership?

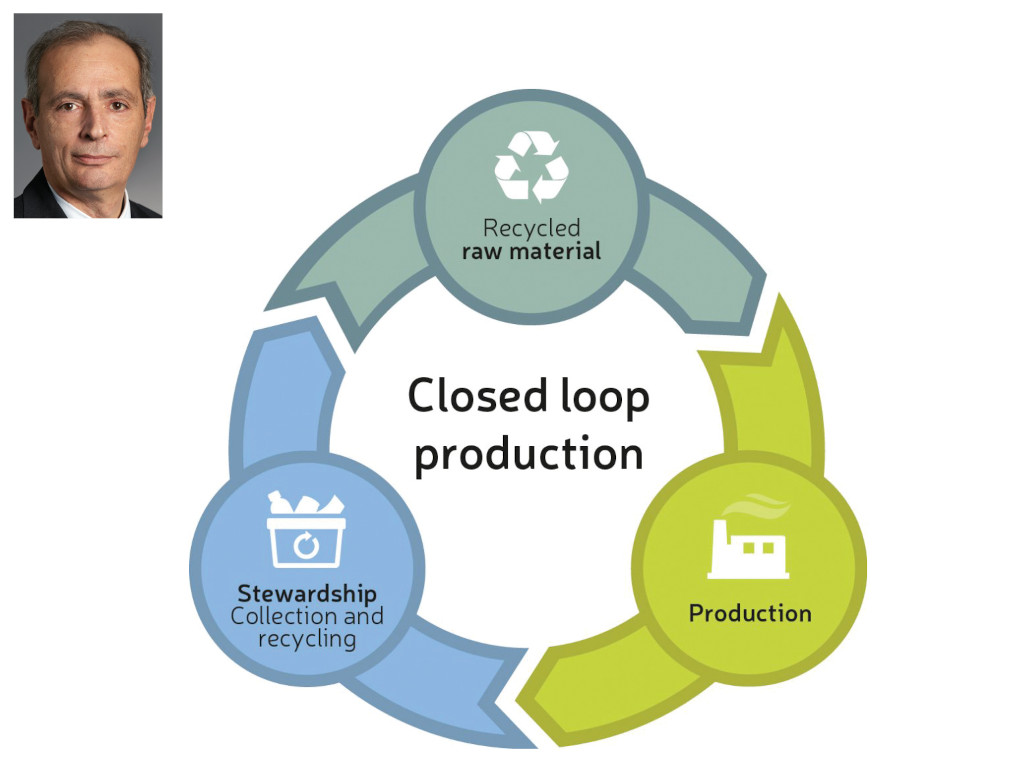

On 30 June, we celebrated the one-year anniversary of the Close the Glass Loop platform (www.closetheglassloop.eu), a multi-stakeholder partnership that brings together the public and private players involved in the glass collection & recycling circular economy – municipalities, brands, producers, recyclers and extended producer responsibility schemes. Together we want to reach an EU average of 90% ‘collection for recycling’ rate by 2030 (up from the current 76%) and to increase the quality of collected glass so that more recycled content can be used in glass production.

The past year has been like no other but despite the unique context, our European and national partners have demonstrated a very high level of commitment.

One of the key goals of Close the Glass Loop is to provide a forum to help resolve common problems and share best practices. To give you an example, hotels, cafés and restaurants (the HORECA sector) have been a major focus of our activities as it is a distribution channel where many products packed in glass are consumed and disposed. In order to increase the overall quantities and quality of glass collected, it is crucial to address the specific challenges of HORECA operators.

GW: What is FEVE’s approach to Deposit Return Schemes?

As I explained, our aim is to have people recycling more and better. We do not believe a Deposit Return Scheme is the right collection system for glass recycling. Data and evidence across Europe shows that including glass in a DRS is suboptimal in terms of both, quantity and quality of recycled glass. Instead, it could have a range of negative consequences and put existing and highly successful collection and recycling systems at risk.

The glass recycling statistics clearly show that the highest recycling rates for glass can be achieved when there is a separate single glass collection system, consistent kerbside and bottle bank collections, and effective public communication initiatives, under a system of Extended Producer Responsibility. The solution is to improve Extended Producer Responsibility schemes and municipal waste management systems that make collection simple for the consumer and optimal for the recycling value chain, not a new parallel DRS.

The situation is different when it comes to refillable glass. Here, the DRS is the best mechanism to get back reusable glass for refill. But the same system should not be used for recycling where bulk collection of all glass is paramount.

GW: What was the motivation for FEVE launching the Glass Hallmark recently (reported in Glass Worldwide January/February 2021, p.100) and how receptive have brands been?

All over the world brands are working with supply chains to improve the environmental and social footprint of products and services. When they choose recyclable glass they reduce waste, CO2 and energy consumption and they avoid migration of chemicals into their products. We want to capture this in one symbol that brands can put on their bottles or labels to convey these messages to consumers. That’s why we’ve created the Glass Hallmark. Brands welcome such symbols. The industry is putting them on standard bottles and convincing brands one by one to do a pilot test. We hope to have the first brands to do this very soon. This will also be accompanied by a marketing campaign in 2022 to consumers which we are very excited to work on right now.

GW: What are the next steps for the Glass Hallmark?

We are working on a marketing campaign to promote the symbol to consumers, brands and glass industries inside and outside Europe. Some people have expressed an interest in the universal symbol of glass and what it stands for so we will be following up on all these leads. 2022 is the UN International Year of Glass so watch out for the symbol to feature strongly!

GW: Does the well-established Friends of Glass campaign continue to have a key role to play?

Yes indeed, this is an extremely successful campaign that has been running for 13 years now and ensured that glass packaging is very popular, supported and followed by literally millions. The figures reached are astounding and a credit to the industry, FEVE and the national associations.

GW: Are the multitude of proactive programmes and initiatives from FEVE clear evidence of the federation’s integral role in ensuring Europe remains a cost effective manufacturing hub for container glass production?

We believe FEVE as convenor of the industry has provided an excellent platform to bring the industry leaders together. Of course any one company needs to operate alone and compete with [others] but when it comes to the common good like sustainability, it’s really no good if we don’t also act as a sector. We have to evolve and adapt together to ensure that glass packaging continues to be the most popular packaging in the world. And that it also continues as the most sustainable. That will not happen on its own. So FEVE is a great vehicle along with the national associations to develop and test out ideas together but also to address problems collectively. The Close the Glass Loop platform is vital to increase collection of our main raw material. This is a good example where companies working together can achieve more than working alone.

GW: Glass Worldwide is FEVE’s longstanding preferred journal. How does this co-operation benefit proceedings?

We appreciate the long-standing collaboration; the magazine is very attentive to ensuring our industry has a channel to communicate to many glass stakeholders. It enables us to highlight what we do but also to ask for help and learn from the glass community that Glass Worldwide brings together.