A globally integrated company with production sites and locations in 15 countries spread across three continents, Gerresheimer has developed a far-reaching international network with numerous innovation and production centres in Europe, America and Asia, utilising its reach and expertise to support customers across the world. The company is one of the leading suppliers for primary pharmaceutical vials/containers and cosmetics and healthcare packaging in the USA glass sector. Gerresheimer currently employs around 1,600 people in America, where it has facilities in Georgia, Illinois, Ohio, New Jersey and North Carolina.

Vital part of the vaccine effort

Over the last 18 months that the world has been battling waves of the Covid-19 coronavirus, Gerresheimer has focused heavily on its products for the pharmaceutical packaging sector and continues to make substantial investments in capacity to support increased vial needs for delivering vaccines.

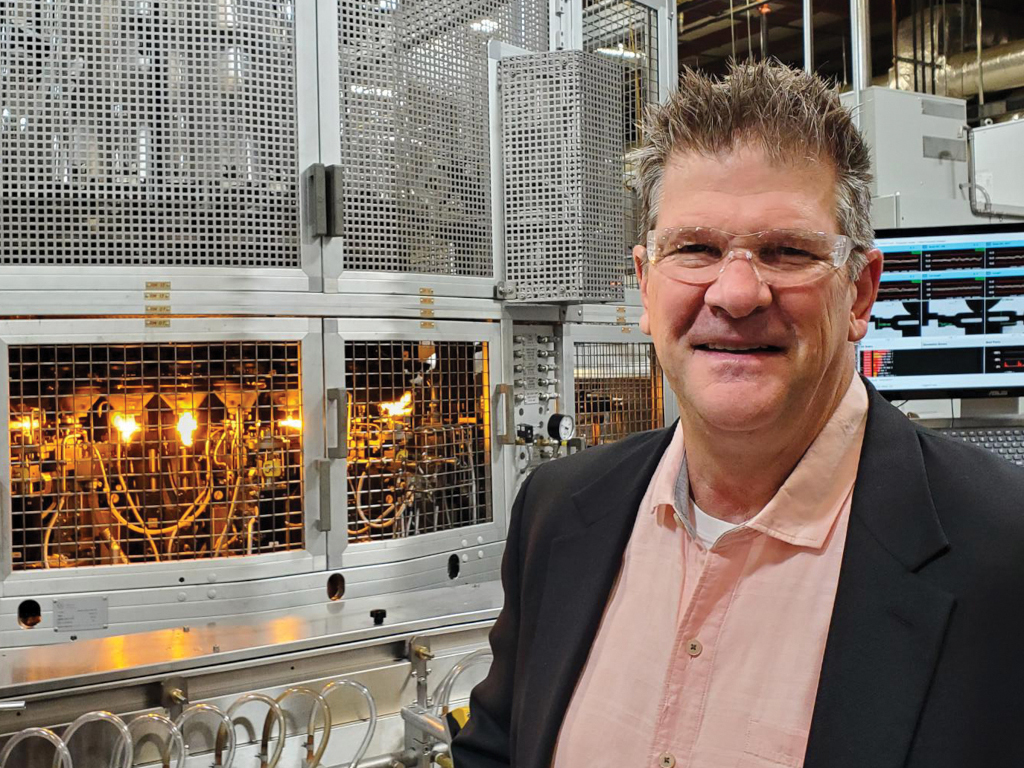

“Gerresheimer is one of the largest suppliers of pharmaceutical packaging globally as well as in America and we have taken a strong commitment to support the pandemic cause by working closely with our filling partners to ensure supply and increasing our investments in both capacity and technology,” explains Gerry Wilkins, Gerresheimer’s Senior Director of Sales & Marketing for USA & Canada. “We are a leading supplier of the primary containers for the Covid vaccine in America, along with other life-saving drugs.”

Supporting the healthcare industry

To enhance the quality and performance of its offerings to the healthcare industry, Gerresheimer is investing at every site in America, not only for primary [glass] containers but also in pharmaceutical plastic packaging and medical devices. Funding is allocated to strategic expansions as well as for developing new technology platforms and providing technical and laboratory support to customers. Recently, Gerresheimer has significantly increased capacity in ready-to-fill (RTF), vials, syringes and specialty vials at its American plants.

“We have multiple plants that can produce a complete product portfolio in order to service the pharmaceutical industry (e.g. vials, cartridges, syringes, ampoules, RTF, drug delivery devices, diagnostic, specialty products…),” says Mr Wilkins.

“With the continued increase in biological products, we have developed a team to focus on this growing sector to ensure we are providing the technology and know-how to support this sector,” he continues. “Our Biological Solutions team continues to experience high demand for this market sector. We are expanding our technical support as well as our laboratory services area in our Centre of Excellence in New Jersey,” reveals Mr Wilkins. “We continue to focus on several digitisation projects to further enhance process control and driving quality to new levels.”

Gx Glass Innovation and Technology Centre

In 2019 Gerresheimer opened its Gx Glass Innovation and Technology Centre in Vineland, New Jersey to drive innovation in pharmaceutical glass, primary packaging glass products, technologies and digitised processes. The facility continues to support the development of new and innovative products and processes as well as providing laboratory testing capabilities. “It also allows us to interact with our customers with our state-of-the-art technology and develop solutions around the challenges,” adds Mr Wilkins.

Along with the benefits of interactive collaboration, the centre enables Gerresheimer to dig deep into quality control by supporting CAPA [Corrective Action, Preventive Action] processes through critical appraisal of internal and external complaints. It has also helped the company to refine its offline inspection systems: to develop improved inspection methods and to perform analysis on customer-specific requirements or problems.

At the time of writing, Gerresheimer is “in the process of purchasing and installing lab equipment required to perform testing and characterisation,” reports Mr Wilkins. “Ninety percent of the equipment has been purchased and installed. Utilisation of the lab services [will] support factories and customers in resolving complaints or product concerns.”

Investments and future plans

At the American plants Gerresheimer places significant importance on its role in sustaining the environment, according to Mr Wilkins. Actions to improve the sustainability footprint of the plants include “reduction in electrical consumption, improved water utilisation and reduction in oil consumption.”

The popularity of Gerresheimer’s RTF vials has fuelled investment in this product range to boost quality and turnover. “We continue to see strong demand for our Elite ready-to-fill product in vials, which offer additional strength and increased line speed on customers’ filling lines,” says Mr Wilkins. “We will continue to invest in the RTF platform. We continue to experience increase demand in providing a solution approach towards the customer’s product life cycle.”

Investments have also been made in the development of forming processes and inspection to improve automation and process repeatability.

“We are excited about continued expansion in the cosmetic sector,” notes Mr Wilkins. “Investments are being made to offer complete solutions made of glass/plastic/caps/seals/droppers and decoration to support our global partners. We coordinate efforts across business units and work together with customers to provide the best solution.”

The company is currently engaged in collaborative projects with healthcare and pharma partners to define products for the future – “for example, wearable devices with a digital platform; bio solution application and disease management focus,” reveals Mr Wilkins.

Plans for Gerresheimer’s American business going into 2022 reflect the confidence of a glass manufacturer with a healthy customer base and the resources and expertise to continue to expand its business. “We have adhered to a strong growth plan since 2019, targeting double digit increases across America business units,” confirms Mr Wilkins.