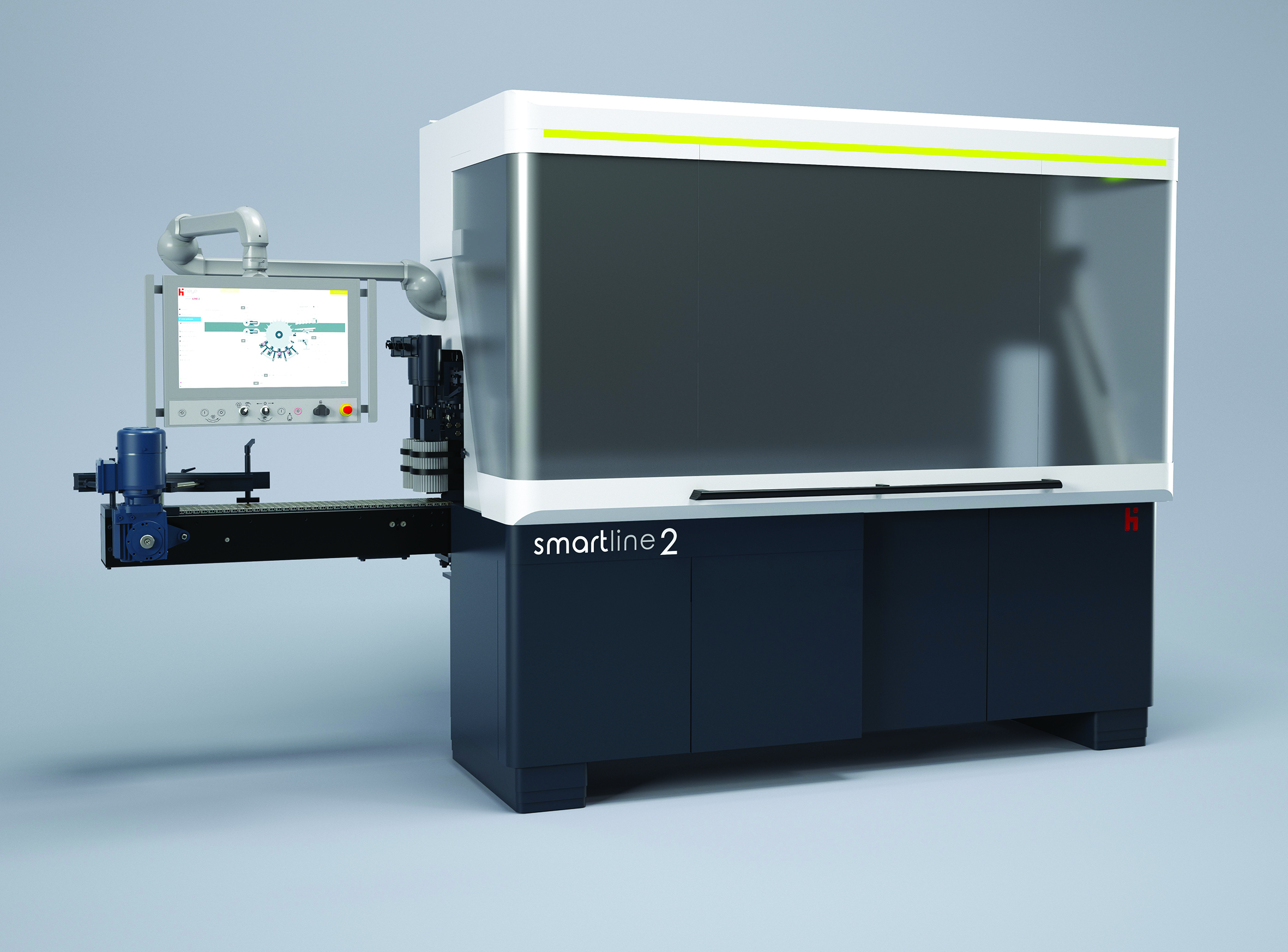

SmartLine 2 is the latest generation of Heye’s starwheel inspection machine series. Developed and manufactured at Heye International’s dedicated Cold End Centre in Nienburg, Germany, SmartLine 2 glass container inspection equipment can be configured in several different ways, with up to six inspection stations available. The Nienburg facility employs a team of experts and features a modern production layout. Importantly, the centre is close to the Ardagh Group’s Nienburg glassworks to undertake essential testing work.

Improved job change times

The application of servo technology results in a high degree of flexibility. Fast and easy changes to an item’s indexing positions and optimal use of the servo torque for up to four rotation stations are possible. Optimised motion sequences allow faster reactions to changing process parameters. The equipment’s innovative design and its large and easy-to-open hood provide more working space between the inspection stations. Job changes become much easier.

The maximum article height accommodated is 400mm (up to 500mm on request), with angular, oval and round containers processed. Thanks to the servo-driven star wheel, indexing positions from six to 48 are possible.

Tooling compatibility

The enlarged working radius guarantees a high compatibility with many existing tooling sets on the market. The tooling range includes a body starwheel, neck starwheel, outfeed guide, centering piece, plug/gauge, stripper and infeed screw.

Flexible inspection options

Among the SmartLine 2’s highlights are faster job changes thanks to the equipment’s improved design and accessibility, the potential to use existing tooling sets and its enhanced user interface. Full data connectivity to all plant information systems is possible, with easy integration into existing lines. As well as featuring the latest non-contact inspection innovations, the equipment benefits from outstanding control reliability to avoid downtime.

Depending on the customer’s requirements, various container characteristics can be checked:

• Tightness.

• Finish diameters.

• Container height.

• Finish and shoulder checks.

• Bottom and heel checks.

• Body checks.

• Wall thickness inspection (non-contact).

• Defects on the finish surface (LOF - line over finish).

• Out-of-round, body diameter.

• Mould number reading (dot code and alphanumeric).

• Dark check inspection.

In addition, the latest non-contact inspection features are integrated, as well as a self-learning system for camera-based check detection.

Reliability and robustness

It is essential for innovations to stand the test of time. In the case of many 21st Century developments, this requirement is achieved by the use of robust industrial electronics and a climate-controlled electrics and electronics compartment, together with high quality components. A touchscreen monitor, simplified access to all electronic components and an extricable mounting plate for frequency inverters and servo controllers enhance operational usability. Hazard-free working conditions for the operator is provided by a microprocessor-controlled safety module.

The machine sets the standard in terms of reliability and robustness. The user interface has been improved and makes job changes as easy as possible. Both the mechanical design and also the control unit are extremely reliable and easy to operate. The large hood gives optimal access to the working space, reducing job change times to a minimum.

Positive feedback

Feedback generated from Heye International customers has confirmed the SmartLine equipment’s robustness and reliability. The mechanical design and drive system in particular are highlighted for their robust design, while the control system is praised for its reliable operation.