James Shang began his career in the glass industry as an electrical engineer and worked in a glass factory for two years after completing his studies. “Since joining Grenzebach in 1998, I have learned many different skills as a commissioning engineer,” he explains. “Then I entered the sales team, where I experienced and developed intensive relationships with the glass customers. With encouragement from customers and colleagues, I gladly took over the role as Managing Director in 2020.”

Grenzebach has been supplying plants for the production of flat glass for decades. “My colleagues and I have been working at Grenzebach for many years; we have accrued great expertise and know our glass customers and their needs and we are happy to support them with our products and solutions,” continues Mr Shang. “Glass is produced all over the world, but even so, we are a family in the glass industry. Most of [Grenzebach’s] employees have been working with us and in the glass industry for many years, so we can speak the ‘same’ language even across different countries.”

Establishing business in China

Grenzebach started business in China 35 years ago, delivering its first glass line to a Chinese customer in 1986.

“In 1993, our Sales Manager at the time, Alfons Reichert, and Export Manager Siegfried Christl travelled to Beijing,” recalls Mr Shang. “Their goal was to inform Chinese experts about the latest developments in the field of glass production. It was a great success: they brought home a new order worth 12 million German marks. Our innovative strength and courage made us believe in the success of the Asian market.”

Company founder Rudolf Grenzebach recognised the potential of the Chinese glass market very early on and in 1998 founded a sales office in Shanghai, followed shortly by an accompanying production facility.

“With the growing demand for glass, more and more glass lines have been established in China; there are now over 300 float glass lines in China and 50% are delivered from Grenzebach,” reports Mr Shang.

At the end of 2019 CNUD EFCO, solution provider for annealing lehrs, tin baths and accessories in the glass industry, became part of the Grenzebach Group (see Glass Worldwide January/February 2022 p56 for the latest developments), enabling Grenzebach to support glass manufacturers with complete production lines from the hot to the cold end. Grenzebach Jiashan now supplies to companies across all of Asia and beyond.

Flourishing flat glass industry

Both the Jiashan and Shanghai sites are part of the Grenzebach Group and “very important facilities” for the company’s Asian business as well as internationally, reports Mr Shang.

“For about 10 years now, we have been manufacturing machinery and equipment at our Jiashan site, which is about 45 minutes by car from the site in Shanghai. For us, local production means less overseas and overland transport is required,” he adds.

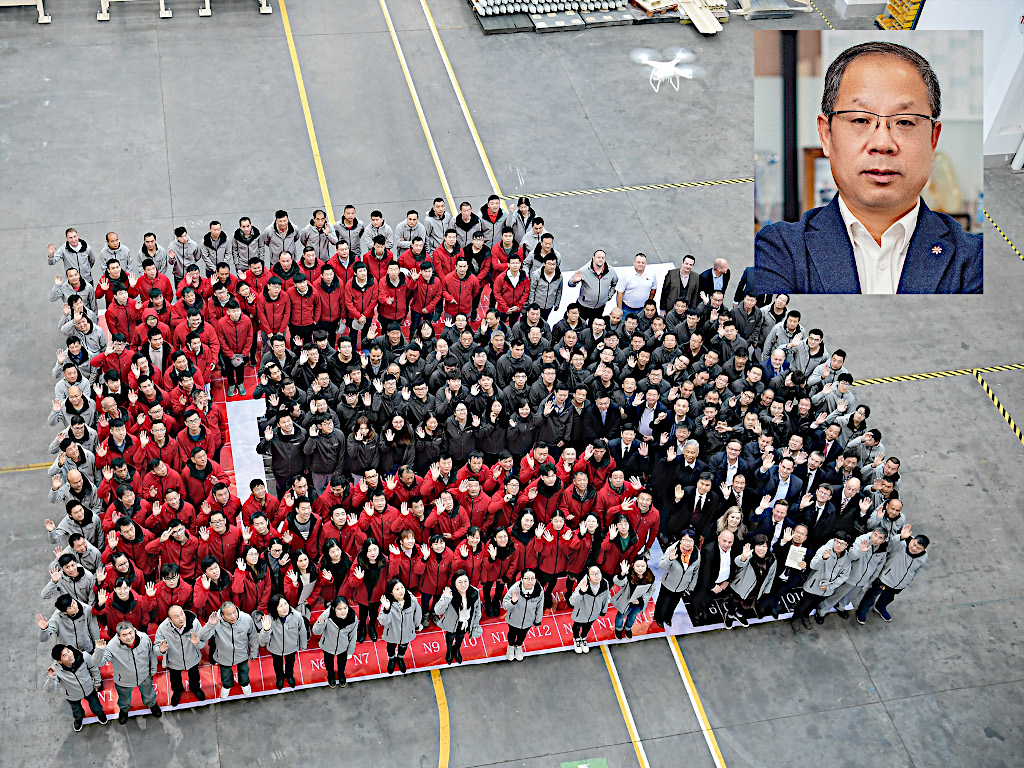

The Jiashan factory has a production area of about 23,000m2 and in 2018, Grenzebach carried out an extensive modernisation of the existing workshops and the office building. In total, 220 employees work in Shanghai and Jiashan across business divisions such as building materials, glass, intralogistics and casting and service/maintenance.

Market conditions in the Chinese flat glass industry are reflecting growing environmental awareness, observes Mr Shang: “All customers recognise that product quality and lower energy costs are key to short- and long-term success. Since glass production is very energy-intensive, climate protection and CO2 reduction are becoming increasingly important for glass manufacturers.”

Moreover, he reports on a number of sectors capitalising on a wider remit of applications for their products: demand for solar glass is increasing year by year; architectural buildings are becoming more modern with more glass; and automotive glass is getting thinner/safer due to a special thin glass application.

Re-entering the pattern glass market

In 2020 the Flat Group encouraged Grenzebach to re-enter the pattern glass market. “We gained their trust with our technology and reputation in the market. We’ve already delivered 28 pattern glass cold ends to flat glass customers; 30 further lines are planned for 2022,” reports Mr Shang.

To meet the increasing demand for solar glass in China, in 2020 Grenzebach’s pattern glass equipment portfolio was extensively redesigned and upgraded with new technology to a state-of-the-art product line. “We listened to the market and learned from the experience,” explains Mr Shang. "That’s why we optimised and customised our pattern glass production equipment to meet our customers’ needs. With this pattern glass product line, Grenzebach is making a major contribution to the use of ‘green’ energy in East Asia."

“Grenzebach’s new pattern glass production technology supports one of China’s megaprojects: CO2 neutrality and green energy,” continues Mr Shang. “China’s leadership places a clear emphasis on renewable energies: on September 22, 2020, President Xi Jinping announced to the UN General Assembly that China will set its climate targets even higher in the future – which means a consistent shift away from fossil energy sources to sustainable ones. The Chinese goal is to reach peak CO2 emissions before 2030 and CO2 neutrality before 2060. To do so, China is rapidly ramping up wind and solar farms, among other things. From 2021 to 2030, the Government plans to add 80 to 160 gigawatts of solar capacity annually. This implies a sharp increase in demand for solar glass, and glass manufacturers will have to respond to it. In China alone, the installation of more than 160 pattern glass lines specifically for the solar market is planned. And the scale of this effect is impressive: the products generated by these plants could cover the whole of Germany with solar panels within nearly two years!”

Solar specialism

Responding swiftly to the energy revolution, Grenzebach offers specialised and ‘continuously improved’ production technology for solar module manufacturers. For photovoltaic applications, ultra-clear glass with high light transmission, a light focusing structure and low light reflection is used. In order to supply high-quality base glass for the solar module, the edges have to be precisely ground and prepared for later use in the solar module, and the sheets are then stacked neatly. In addition to offering robots with high stacking accuracy, Grenzebach supplies conveyor and automation technology to transport raw glass for further processing, focusing on high-precision and gentle treatment of the sensitive substrates.

With Grenzebach’s pattern glass lines, glass thicknesses from 1.5mm to 6mm are possible. Manufactured glass plates range from 1,200mm x 2,400mm to 2,650mm x 2,800mm – a perfect match for Chinese solar panels. The capacity of one line varies typically from 125 to 300 tons per day.

“Knowing that the glass production equipment of our customers never sleeps, our service team also plays an important role,” adds Mr Shang. Grenzebach takes care of maintenance and service over the entire lifecycle of the line, and experts at the company’s manufacturing site in Jiashan close to Shanghai support Chinese plant operators in making optimum use of pattern/solar glass lines and furthermore, can also supply spare parts at short notice.

Global support and communication

Although travel restrictions due to Covid-19 are still (at time of writing) making commissioning projects more difficult for Grenzebach, Mr Shang also sees this as an opportunity for the company’s local engineers in China. “They are taking on more tasks with the remote support of colleagues from overseas and developing [their skills] more and more,” he explains.

“Grenzebach is a global group with strong links to our regions and can interact locally and globally,” he continues. “We share ideas and processes daily to learn from each other, constantly pushing ourselves to develop. We support each other globally and work strongly together as ‘One Grenzebach Group’ to serve all our customers even better.”

Noting that China Glass 2021 was “very successful”, Mr Shang is encouraged by more face-to-face connection at this year’s event. “We’re looking forward to China Glass 2022 and to seeing our Asian customers again,” he enthuses. “I would like to take this opportunity to thank all our customers for their trust and for the good collaboration they have with Grenzebach,” he concludes.

Image: 220 Grenzebach employees in Shanghai and Jiashan work for the company’s glass, gypsum, intralogistics and casting divisions (inset: James Shang).