4.0 technology introduced for scraping conveyors

Poland’s leading batch plant and furnace technology supplier is at the forefront of factory operating changes, where machines are able to make decisions by themselves or at least make the decision-making process easier for humans by seamlessly communicating with them.

The Forglass R&D department, in collaboration with The Main Mining Institute in Katowice, AGH University of Science and Technology in Krakow and other prestigious technical universities, has developed an array of innovative technological solutions for both batch plants and furnaces.

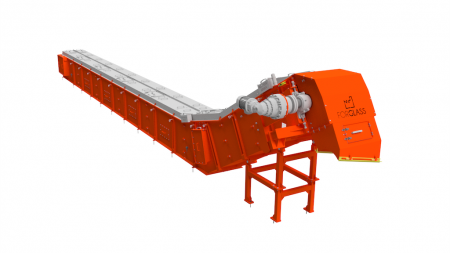

In the pursuit of maximising production and minimising costs for its clients and even more importantly to improve safety, Forglass has developed an ‘intelligent’ scraping conveyor, named SmartScraper (illustrated). Equipped with an overload protection system, the design uses electronic sensors to continually monitor the working conditions of the conveyor, diagnose problems and react instantly to changes in operation.

The machine’s built-in intelligence allows it to slow down or stop before its elements are damaged, including the protection system itself. Additionally, when connected to a comprehensive array of sensors (eg temperature, working speed or efficiency), SmartScraper allows detailed analysis of its performance to avoid future malfunctions.

Forglass has already delivered a number of SmartScrapers to clients’ factories, including packaging, float and glass fibre production facilities. The feedback generated has been positive, leading the company to offer SmartScrapers equipped with OPS as the only option in its family of scraping conveyors.