EME offers intelligent cullet scraper control

Producer of batch and cullet treatment systems EME has applied intelligent control to its cullet scrapers to reduce wear and to save energy and labour.

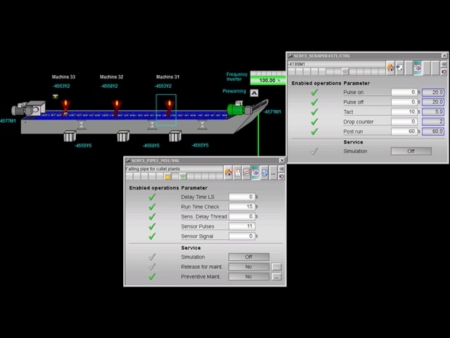

Via interfaces with a customer’s IS machines, whether gobs or continuous trickle, EME’s control system intelligently determines the quantity of glass fed into the scraper conveyor and automatically adjusts running times and running speeds to optimise the system performance. In this way, changes in glass production are compensated for independently and without the intervention of an operator.

Other operating modes are implemented for the operation of the scraper conveyor, as well as monitoring water temperature, automatic water addition and run time monitoring.

In addition, EME can extend its cullet scraper solution to include its closed loop cullet return technology that allows for cullet to be automatically reintroduced into the batching process without any operator intervention or manual handling of the cullet. All of this functionality is readily available on a mobile device, making the system accessible from anywhere at any time.

EME’s intelligent control system is included as standard with all scraper controls that have a PLC. The company’s standard function modules are available as tailor made solutions for customers.

View EME‘s presentation in the Virtual Marketplace: www.glassworldwide.co.uk/virtual-marketplace. The full version of the above news has been published in the May/June issue that has been posted globally and is available to read free of charge in the Digital Archive (sponsored by FIC) at https://www.glassworldwide.co.uk/Digital-Issues