Glass Service Italy advocates electricity to cut carbon and costs

To reduce emissions in the glass industry in line with EU targets for carbon reduction, Glass Service Italy (GS) has developed an electric heating system for forehearths that compares strongly on sustainability numbers against its counterparts, gas, oxy fuel and hydrogen.

Electric heating technology offers a potentially carbon-free source, removes combustion gas (which can be expensive or sometimes unavailable), and provides better heat conversion efficiency, greater insulation (no need for gas exhaust chimneys) and improved installation and customisation options.

With hydrogen still in the testing phase, electric heating is the arguably the best option for now, believes the company.

Glass Service Italy’s electric heating system generates 0kg/h of CO2 compared to 24.38kg/h for gas power, the same for air-gas and 7.99kg/h for oxy-gas (this refers to a standard zone with L=2860mm).

Moreover, electrical heating systems also run at 2.88 euros per hour compared to 4.42 euros for its air-gas counterpart, and finally, but perhaps of most interest, running energy costs are reduced by 40%.

The choice moving forward is becoming increasingly clear and Glass Service Italy is ready to work with customers to achieve better results for both the carbon footprint and the economic cost of glass manufacturing.

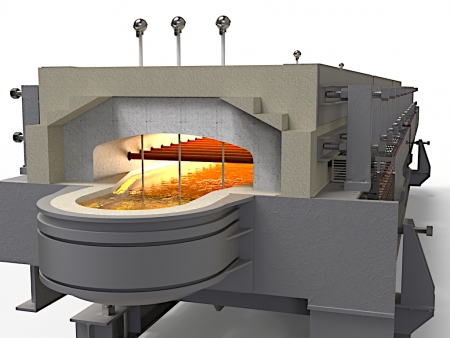

Image: GS believes electric melting is the best option for a sustainable glass industry.

Check out Glass Service’s entry in the Virtual Marketplace: https://www.glassworldwide.co.uk/virtual-marketplace