Improve glass quality and reduce energy consumption with thermal imaging from AMETEK Land

Glass manufacturers face many challenges in their daily operations, including the need for accurate temperature measurements in a variety of locations within the glass-melt furnace.

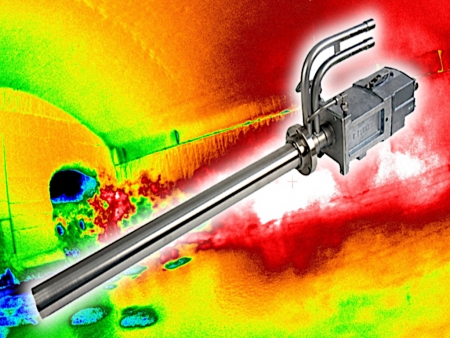

A portable infrared thermometer, such as AMETEK Land’s Cyclops C100 L pyrometer, provides accurate, calibrated, and traceable temperature readings of molten glass from different positions around the melt tank.

This can be supplemented by the company’s NIR-B-2K-Glass imaging camera, available for fixed installation or as a transportable version, which adds significant advantages compared with visual imaging and point-temperature measurements.

The NIR-B-2K-Glass imaging camera produces high-definition thermal images; it can also take measurements between 600°C and 1800°C from any point in the image.

A permanently installed thermal imager actively records all necessary and useful data, allowing the video to be stopped at any frame.

This means measurements can be taken of all ports at exactly the same point in the process, allowing reversals to be tuned more accurately.

Structural damage caused by high temperatures can also rapidly be detected before it turns into a major problem.

If a crack is developing in the refractory, it can show up as a cold area where the air is being pulled in. The NIR-B-2K-Glass imaging camera accurately profiles the temperature of the entire furnace through a small opening in the furnace wall.

Increased melt tank efficiency, improved product quality, and reduced process costs are achieved through monitoring the live thermal video inside the melt tank, reinforcing the key measurements provided by the Cyclops C100L.

Philippe Kerbois, Global Industry Manager – Glass, said: “Using thermal imaging in glass operations results in many measurable benefits. Operators can, in a safe, timely way, collect valuable data that they can utilise and store while ensuring the quality of the glass and extending the life of the furnace. This all leads to reduced costs and an improved process, as well as working towards reduced emissions and carbon footprints.”

Image: Infrared thermal imaging with AMETEK Land.