Boosting scraper efficiency

Germany’s ZIPPE has been active in the field of internal cullet recycling and the supply of scraper conveyors to the international glass industry for many years.

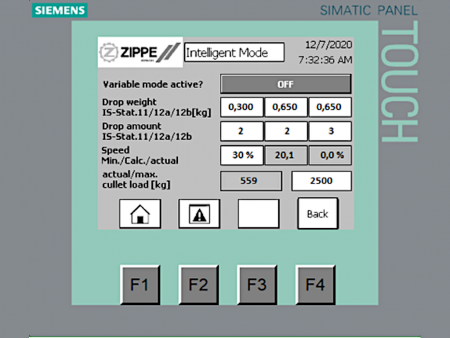

Reducing wear and minimising the proportion of fine material are assisting customers to avoid their scraping conveyors from running for longer than needed, due to changing production conditions. This situation causes unnecessary energy costs and excessive wear. To overcome these issues, ZIPPE has developed the innovative ZMART scraper control system.

Depending on gob weights and number of gobs, this intelligent control module decides if and how fast the scraping conveyor operates. Furthermore, the required operation time is individually calculated and minimised.

The production data necessary for this calculation are provided automatically via simple standardised interfaces between the IS machines and the control system of the scraping conveyor.

If required, these parameters can also be entered and adapted manually, which allows the continuous and individual optimisation of the process. Thus, operation time is reduced to the necessary minimum.

The ZIPPE ZMART scraper control has been operating successfully at O-I´s facility in Bernsdorf, Germany since August and shows a stable, safe and efficient operation with positive results.