Safety glass laminating with easy-LAM IFL gains certification

The 2018 launch of the easy-LAM IFL for inline lamination of flat glass was a significant milestone in the history of BÜRKLE.

The newly developed technology enables flat and laminated safety glass manufacturers to replace the cost- and energy-intensive autoclave in their production with a highly efficient lamination process.

The three-stage laminating concept, which consists of a heating, vacuum and cold press and can be fully integrated into new or existing production lines, is decisive for the savings.

After successful installation of the test system of the "IFL-Process" in the BÜRKLE Technology Center, development and test trials with partners and interested parties can now be carried out at the Freudenstadt site.

Thanks to the test system, another important part of the development strategy has also been completed: certification according to the quality standards DIN EN 12600 and DIN ISO 12543-4.

With this step, the company has confirmed the promised quality standards with regard to breakage, temperature and irradiation safety. "The certifications according to DIN standards are a central part of being able to guarantee our customers the highest end product quality. It makes us all the happier that we have achieved these standards after intensive process development," says Robert Gaiser, Sales Manager Glass Division at BÜRKLE.

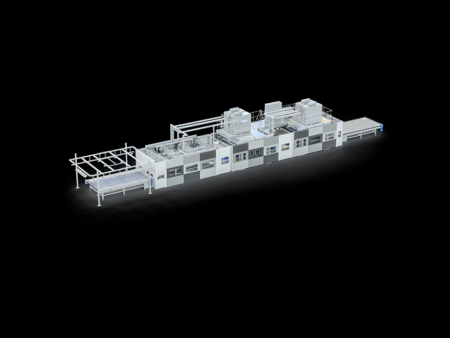

Photo: The easy-LAM IFL from BÜRKLE is characterised by low energy consumption compared to autoclaves - BÜRKLE