Supporting reliable production at Italian glass plant

As production managers adjust repair schedules due to the Covid-19 pandemic, safety and reliability are a frequent concern. Vetrerie Riunite Group, a leading Italian company in the manufacture of hi-tech glassware, has taken precautions to ensure furnace reliability amid Covid-19 with the assistance of a SmartMelter inspection.

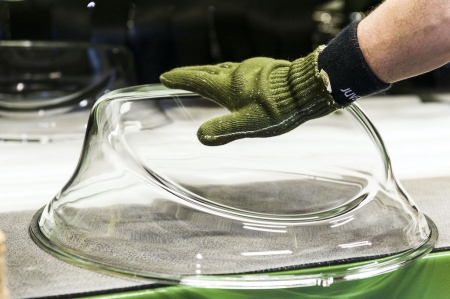

Because hot spots had been observed in the throat area of the furnace, the glassmaker contacted PaneraTech to determine the condition of the sidewall and throat refractory for overcoat optimisation. The results of a SmartMelter inspection confirmed that some additional cooling measures were necessary on the throat. The report showed the cover block residual refractory thickness to be less than 40mm in the thinnest areas, with the majority of measurements showing < 5 mm residual thickness.

Within a week of SmartMelter reporting, the cover blocks were cooled with compressed air and water and overcoating was installed. “We have had to make changes to our operations like everyone else” explained Giuseppe Velli, Plant Manager at Vetrerie Riunite. “However, the importance of plant safety and furnace reliability does not change. The SmartMelter inspection gave us the information needed to continue operating safely and to prioritise repairs.”