AI-enhanced sorting offers environmental advantage

Inspection may not be the first area the glassmaker thinks of when it comes to decarbonisation. Yet, as Alexandre Tan from IRIS Inspection Machines told the 45th ASEAN Glass Conference, AI is changing inspection and helping container glass manufacturers to optimise waste while reducing their carbon footprint.

In the glass industry, production efficiency is not just the key to commercial success but vital to conserve energy and cut emissions. Non-saleable glassware is a waste of time, money and resources – both raw materials and energy. Reducing the waste of all three of these is the ultimate way to improve environmental performance, whether the power comes from renewable or finite sources. And most glass manufacturers use pack-to-melt ratio as their core metric to measure this efficiency.

Carbon emissions are generated throughout the glassmaking process; from quarrying and raw material supply, batch mixing, melting and forming, transportation, packing and, of course, inspection and quality control.

If you look at the process in isolation, inspection machines only seem to create indirect emissions from the electricity consumed compared to hot end. Therefore, it is important to see how improvements in cold end inspection can enhance decarbonisation over the complete process.

Enhanced sorting

Firstly, better inspection means more precise rejection rates increasing pack-to-melt. More importantly, sending relevant inputs about rejections to the hot end (the biggest CO2 emitter) leads to quick response there, so rejects can be cut at source. Precise rejection means more bottles that are within specification get through to the customer, while better communications with the hot end accelerate changes, so fewer unsaleable bottles are made in the first place. False rejections are bad news; they indicate the manufacturer needs to melt the glass twice to produce one good bottle.

Markets have different views on the impact of imperfections. The perfume industry, where high cosmetic quality requirements dominate, inevitably expects a higher rejection rate than food or beverage companies. A small cosmetic defect can be crucial to a perfume brand, whereas critical safety faults will mainly concern the beer bottler [and] some minor blemishes may be acceptable.

What IRIS seeks to eliminate is false rejection. While small in number, these can have several root causes. Some are due to control imprecisions and the technologies employed. Others are caused by human factors, such as training, skills, or basic and instinctive human mistakes. They all have a direct impact on the carbon footprint as they all demand that fresh bottles are made to supply the customer with an acceptable delivery. The answer to all these challenges may lay in Artificial Intelligence (AI).

AI’s role in glass inspection

IRIS has long been a pioneer in developing AI in its systems. Since 2018, the company has put more and more tools into robots’ hands and given its technology the capacity to learn.

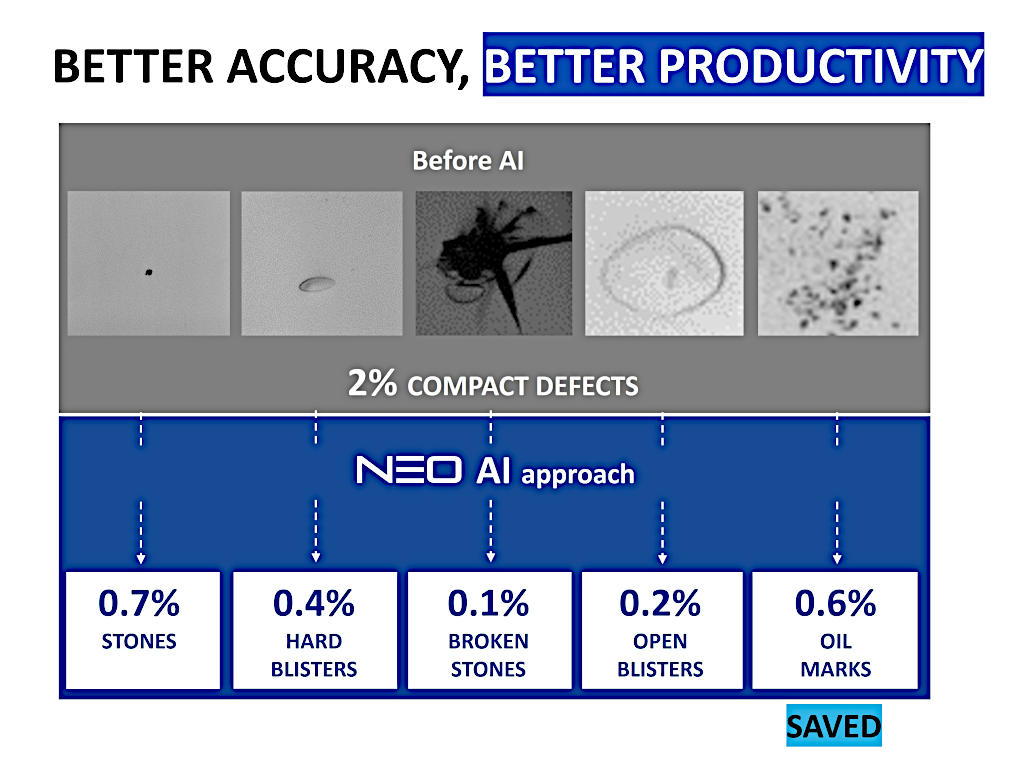

AI mimics the human brain. We do not just see stones – we see inclusions, broken stones, unmelted cullet. It’s the same with surface blisters and hard blisters, cracks and folds or oil marks and washboards. In other words, AI identifies defects with the eyes of a glass expert, meaning it differentiates between critical defects and mere imperfections. This has a positive effect on productivity, quality and indirectly on the energy consumed in glassmaking.

Before AI, an inspection machine would, for instance, count 2% of rejection while rejecting all same family defects in the same category. Now, with AI, IRIS identifies those defects as 0.7% stones, 0.4% hard blisters, 0.1% broken stones, 0.2% open blisters and 0.6% oil marks. Not only is this much more precise, it provides more actionable information to the hot end team.

Moreover these 0.6% oil marks, identified as non-critical defects with AI, could be saved.

AI-driven inspection offers richer classification of defects; identification of critical defects and a tolerance of acceptable blemishes; a reduction in false rejection and faster corrective action.

The development of iBot

The next questions for the IRIS research and development team was “How do we harness AI to create the best result for customers?”

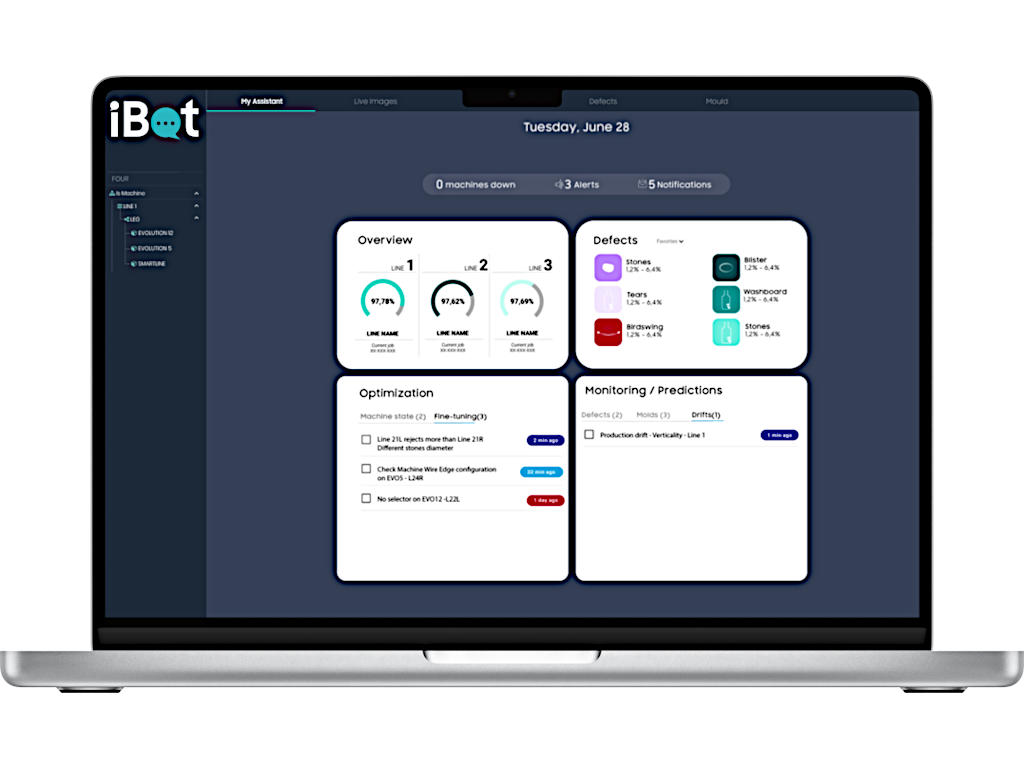

IRIS’s team of experts has dug even deeper into the process, to provide the best solution for industry 4.0. The result is the creation of iBot, an intuitive tool offering ultra-comprehensive analysis for operators and managers in the hot-end, cold-end, and quality control teams.

In real time, iBot uses its bespoke web app to predict process defects and communicate immediately with hot end leaders and operatives so they can take corrective action.

While a classic MES (Manufacturing Execution System) provides alerts on the rejection rate and maybe shows pictures, iBot goes further. Indeed, iBot gathers all information from any Evolution machine connected to it, from the adjustments parameters to every measured values of each bottles inspected on any given section. iBot processes in real-time this data and can give adjustments priorities to be implemented on each machine. It will also prioritise the main defects, even when these are constantly evolving.

On top of these skills, iBot can identify drifts in production, section by section, to facilitate corrective actions without delay, thus preventing the machines reaching critical limits and rejection.

In short, iBot makes the most of AI. It provides:

- Exceptionally detailed analysis.

- Repeatability and accuracy.

- Predictions of drifts and systemic defects.

- Accurate information including origin and criticality.

- A simple set-up for a fast job change.

iBot provides the right information at the right time and to the right person – on the machine itself or remotely – to help monitor performance and initiate potential changes.

This comprehensive use of AI results in the prevention of errors and an improvement in pack-to-melt, a slew of critical information for future manufacturing, and the conservation of energy, effort and resource, thus boosting productivity.

Conscious of inspection’s role in the industry, we truly believe that reducing rejection rates while keeping a high pack-to-melt ratio will deeply impact positively the glass industry’s carbon footprint.

IRIS Inspection machines, Bron, France

web: www.IRIS-im.com