Hybrid versatility

A hybrid ink line, the LEDGF range is formulated for LED curing, but can also be overprinted with a protective layer of highly transparent varnish and cured under UV light. In this way, the application saves energy at each LED ink station and is also as safe and reliable as a UV system. It is a cost-efficient solution because most modern printing machines are equipped for LED curing followed by UV curing.

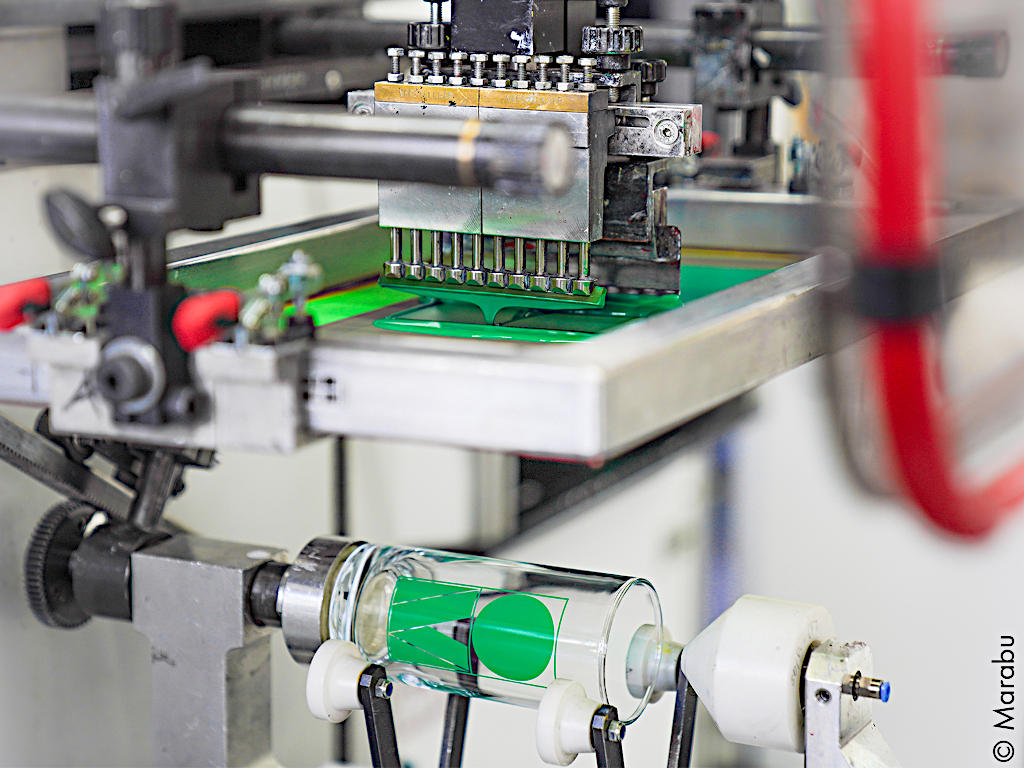

UV-LED inks can also be cured conventionally, using UV light alone. This means glass manufacturers can use their existing machines and don’t have to invest in expensive new equipment.

Ultra Glass LEDGF is available with print-ready viscosity and in Marabu’s Ultracolor range.