Ambitious targets

Along with taking a long-term approach, Corning is working on shorter-term actions to reduce carbon emissions from its operations. The company believes that reducing its environmental footprint is a core responsibility as a global corporate citizen and is an increasing expectation of stakeholders. Corning is working to reduce its negative impacts on the environment throughout its operations and value chain by reducing natural resources consumed, emissions produced, and waste generated.

Corning has committed to a 30% reduction (absolute basis) in its Scope 1 and 2 greenhouse gas (GHG) emissions by 2028 from a 2021 base year, and to a 17.5% reduction in its absolute Scope 3 GHG emissions, covering purchased goods and services, capital goods, fuel- and energy-related activities, and upstream transportation and distribution by 2028 from a 2021 base year. These near-term reduction targets were recently validated by the Science Based Targets Initiative (SBTi) as ambitions aligned with the 1.5°C trajectory in the Paris Climate Accord.

To help achieve these ambitious GHG emission reduction targets, in mid-2022 Corning joined Glass Futures – a not-for-profit organisation that is working to ensure the future of glass manufacturing is built on high value and fully sustainable, zero-carbon products. Corning is also an active member of the GlassTrend organisation – a consortium of worldwide operating industries and institutes working in the field of glass and glass production – to help advance the company’s knowledge base related to long-term manufacturing sustainability efforts.

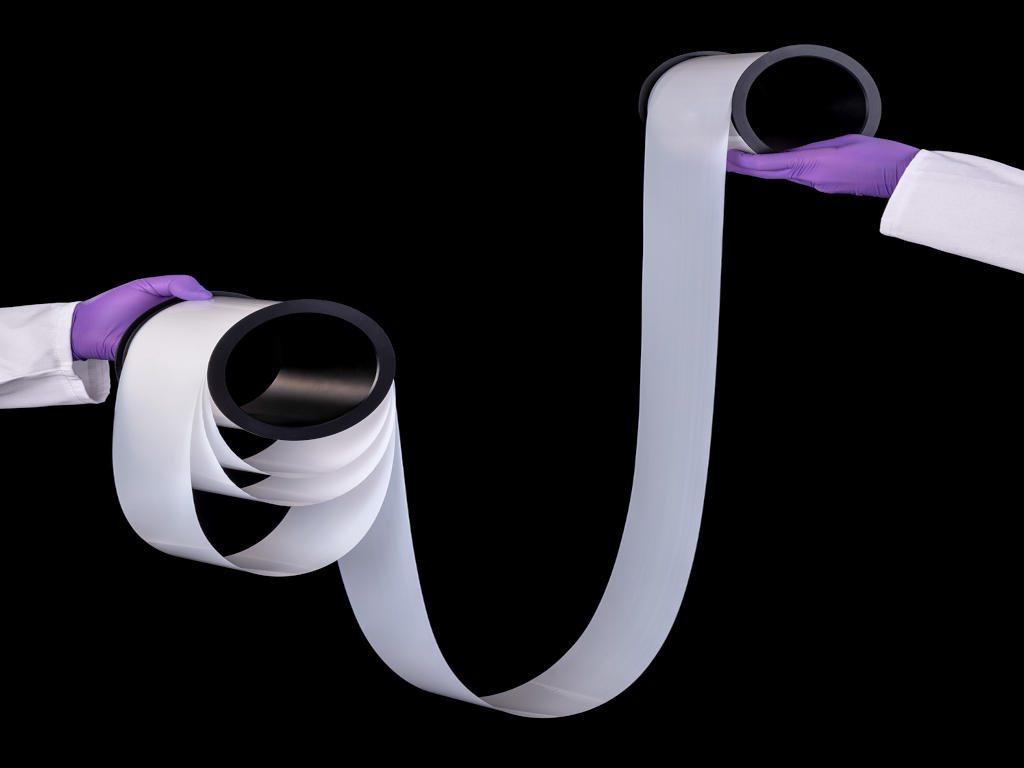

Paired with these efforts, Corning is working on reducing the greenhouse gasses from its proprietary melting and forming processes. Corning is a leader in the amount of electric usage in its melting platforms for specialty flat glass today and is continuing to drive towards processes that rely 100% on electric melting. Additionally, Corning’s research organisation is investigating the use of non-fossil fuels, such as hydrogen, as part of a larger program to understand future opportunities for low-carbon melting practices.

Corning’s innovation engine has, and will continue to, provide meaningful environmental improvements that will help move the world forward, while also working to drastically reduce the amount of carbon emissions from its operations.

*Assumptions for the comparative analysis of the hot form process assume similar geographical region and were collected through expertise from in-house hot forming for other types of automotive glass, industry research, expert opinions, and third-party evaluations. Models for the hot form process are representative of theoretical data. Sensitivity analyses were conducted to account for the potential variances in environmental impact that could occur based on the collection of primary data for the hot form process.

Corning, Corning EAGLE XG and Corning Gorilla Glass Victus are registered trademarks of Corning Incorporated