ACMOS Chemie showed its range of release agents, coatings and shear blade lubricants. The portfolio of innovative process aids presented included cooling lubricants for shear blades, high-temperature resistant coatings for blank and finished moulds, neck rings and delivery system (trough and deflector), release agents for blank and finished moulds as well as neck rings, sliding agents for conveyor belts HE and CE and coatings for rotary blow production.

glasstec 2022 review

Following a pandemic-induced four-year break, glasstec’s restart welcomed 936 exhibitors from 47 countries and hosted 30,000 visitors from 119 countries who came to experience the operational excellence of the sector.

An array of international companies presented the latest technology, including the following selection from the glass manufacturing and processing sector (for a full list of exhibitors, visit www.glasstec-online.com). The full version of this review (with stand gallery photographs) will appear in the Nov/Dec 2022 issue of Glass Worldwide.

Adelio Lattuada promoted a series of flat glass processing innovations, including robotic solutions (CNCs, double-edgers, cutting, tempering or IG lines etc).

Advanced Energy Industries displayed its latest temperature measurement and plasma power supplies for the production and coating of flat glass, solar glass, container glassware, utility glassware and technical glass products. Visitors saw how the company’s non-contact thermometers, power controllers and DC plasma power systems have been tailored to the specific needs of the glass industry.

Among the power technologies exhibited were advanced RF, pulsed-DC, and bipolar pulsed-DC power supplies featuring sophisticated arc management capabilities and digital SCR power controllers that increase performance control accuracy.

Thermal monitoring demonstrations featured non-contact thermal imaging and flexible pyrometry platforms for the robust and precise temperature measurement that is critical for efficient and cost-effective melting, glass viscosity control, heat zone adjustment, annealing and stress reduction.

AGC Ceramics exhibited as a recognised refractory manufacturer with over 100 years’ experience and a proven supplier of complete furnace engineering services.

AGCC proposed to visitors an excellent furnace concept in terms of energy saving and environmental-friendliness, with reasonable and workable refractory selection.

The fusion of material technology and engineering knowledge helps AGCC to support customers in various furnace life situations.

AGC Glass Europe promoted the flat glass it produces, processes and distributes for the construction, automotive and solar sectors. The manufacturer highlighted its Planibel coloured float glass available in dark grey, bronze, grey and green, as well as three blue tinted shades: PrivaBlue, Dark Blue and Azur, and explained how a special chemical composition gives the architectural glass a softer or more intense colour tint, depending on the thickness. Also featured for interior use was AGC’s ecologically-produced Mirox MNGE range, and Mirold Morena: mirrored glass with a distinctive antique look achieved by selective oxidation of the silver coating. AGC held a press conference at Messe Düsseldorf to announce that by the end of 2022 it will produce a float glass range featuring a significantly reduced carbon footprint of less than 7kg of CO2 per m2 for clear glass (4mm thick). This move will enable AGC to reduce the carbon emissions generated during the production of this float glass by more than 40%. The group is taking a “holistic” approach to its low-carbon glass production, incorporating sustainable sourcing of raw materials, highly efficient melting furnaces, green energy sources and increased use of cullet, as well as optimising transport between Group sites for finishing processes, and optimising the transport for finished products. AGC Glass Europe’s production plant in Moustier, Belgium, will be the first site to produce low-carbon glass, as it has already been successfully converted to meet the strict conditions required.

Agr used glasstec to unveil the ThicknessPen, its new portable thickness gauge for accurate, non-destructive measuring of glass containers and sheet materials. Featuring patent-pending dual measurement mode technology, the app-based device gives users the option to measure using either a magnetic or capacitance mode, whichever is most appropriate for the application. Agr’s stand also highlighted its Gawis4Glass dimensional measurement system for glass containers. Designed to streamline laboratory measurement operations by performing a multitude of critical dimensional measurements in one simple procedure, the system can be used for a wide range of glass containers and offers “unmatched” accuracy, repeatability and operational throughput. Another new development on display was the RPT3 pressure testing system for glass containers which has the ability to test two bottles simultaneously via dual pressure generators. Pressure tests up to 69.8 bar can be performed on high-strength bottles as well as on low-pressure ware with accurate detection of low-level breaks as low as 1.4 bar.

All Glass proposed flexible and innovative depalletising, conveying and palletising solutions.

The All India Glass Manufacturers’ Federation (AIGMF) shared a stand with preferred partner, Glass Worldwide.

Manned by General Secretary Vinit Kapur, the stand was visited by many figureheads from the Indian glass industry, including a number of AIGMF committee members.

Founded in 1944, AIGMF is the sole representative body for all segments of the Indian glass industry, consisting of large, medium and small-scale manufacturers.

AMETEK Land showcased a wide range of temperature measurement technologies for use in a variety of glass applications, from melting to annealing. Highlights included the NIR-Borescope-2K-Glass (NIR-B-2K-Glass), a short-wavelength radiometric infrared borescope imaging camera, designed to produce high definition (1,968 x 1,476 pixels) thermal images, along with providing accurate temperature measurements from any of the three million temperature points in the image.

The camera measures temperatures in the range 1,000–1,800°C (1,832 to 3,272°F) and is suitable for float glass, container glass, borosilicate glass, and fibre glass melt furnaces.

Antonini displayed a full range of annealing and decorator lehrs, together with lehrs for glass blocks, lehrs for HV insulators, mould preheating kilns, cold end spray systems, upgrade and overhaul services.

The success achieved throughout the company’s existence is born from a tradition in which the search for technological improvement is founded on reliability, efficiency and a willingness to listen to the demands of customers.

Applied Vision, a member of the Antares Vision Group, invited showgoers to learn more about its soon-to-be launched Volcano Check system, which will join its Volcano Sidewall (SW) and Volcano Sealing Surface & Base (SSB) inspection solutions for glass containers. Volcano Check is designed to completely change the way plants look for and detect even the most problematic checks while greatly reducing set-up time, machine operator burden and unplanned downtime. Using just two multi-axis imaging stations, each built around patented illumination and optics, the new system eliminates both the need for machine operators to manually align multiple sensors, and for container-specific tooling required for rotation. To support ease of use, a finish-specific tool provides the ability to make pass/fail decisions, while requiring no machine training or calibration (instead, a simple setting adjustment for the bottle being inspected allows for fast job changeover). Volcano Check also features a self-learning AI-based tool that users can ‘train’ to automatically start inspecting. Volcano Check, SW, and SSB are designed as standalone or electronically coupled solutions. Installed together, the machines can provide mould-correlated statistics as well as image maps of check locations to give users a broader view of the container being inspected and a better idea of where manufacturing process problems may exist.

Area Impianti, supplier of flue gas treatment systems throughout the world, offered visitors know-how and advanced technology to treat the polluting gases produced by industrial processes of flat, container, tableware, artistic, borosilicate and lighting glasses, as well as glass wool.

Highlights from solutions on show included flue gas treatment – DeNOx SCR and heat recovery for thermal and/or ORC electric production.

Ardakan Float Glass Co from Iran discussed with visitors the products it exports to over 68 countries and explained why the company is renowned for the glass it manufactures for the overseas racket sport ‘padel’, which is played in 20m x 10m courts requiring strong glass walls as balls can be played off them in a similar manner to squash.

Arkema exhibited as a glass coating market and technology leader, supplying coatings and systems for value-added products used in the flat and container sectors.

Avacon promoted a wide range of advanced products and innovative solutions to visitors from the hollow glass industry, especially in the field of process automation and improvement. Innovations developed for the IS machine include a standalone servo pusher, servo invert, servo take out and proportional valves control, among other solutions. In addition, Avacon promoted vision systems such as GobScan 2D, GobScan 3D and the IS machine surveillance system, Sentinel.

Quality control and production technologies specialist Ayrox welcomed glass processors to its stand, offering equipment and solutions including QC equipment and services, non-destructive optical control equipment, training, PVB treatment, PVB wiring machinery and production accessories.

BASF showcased high-quality optical pyrometers, thermocouples, and calibration services to provide temperature insights that can enable higher yields and assist customers with attaining increased profit, including the EXACTUS instruments to supply accurate temperature readings. Other innovations included Fibro platinum to Platinel thermocouple wire.

Bavelloni, historic manufacturer of machinery and tools for flat glass processing and Techni Waterjet, one of the oldest and most experienced waterjet manufacturers in the world welcomed visitors and offered them the opportunity to experience first-hand their complementary glass processing solutions, to watch live demos and meet the companies’ experts.

BDF Industries was present as leader in glass engineering, renewable energy and industrial automation. Visitors were presented with the innovation, technology and versatility benefits that make BDF IS Machines ideal solutions for high productivity, low maintenance effort and considerable energy saving. Highlights on show included the new Servo Baffle and Servo Blowhead Mechanisms, promoted by BDF as a ‘revolution’ not only because of being fully electric but also due to their retrofit action as they can be applied to every single machine. Nicolas Trentin, Marketing Manager, told Glass Worldwide: “After four years without glasstec, it was great to see such an active community and was important for us to meet customers and suppliers, finalising many projects. Many people visited us and with an always fully crowded booth, for us was an important signal since we get the confirmation that we are a strong point of reference in the industry. We take the opportunity to present ourselves in a completely different way, launching our brand new logo and website and bringing on the trade show floor a representation of the process of a glass container creation, revised in a conceptual way and creating an immersive experience for guests who visited our booth.”

Bernard et Bonnefond promoted ways to save money for electric furnaces and electric boosting with its variable voltage transformer.

Bertram Elektrotechnik exhibited as a specialist with in-line control and automation systems for the cold end of the glass container manufacturing process.

Biesse displayed a selection of solutions for machining glass including: robotic island for automatic loading and unloading, machining centre with innovative MTS system, integrated cutting line with storage and handling systems, integrated double-edging grinding line with boring-milling machine, integrated flexible double-edging grinding line with boring-milling machine and storage device for optimising the glass flow.

Binder+Co presented CLARITY, the company’s development for sorting glass efficiently, starting at a size of 1mm. CLARITY turns glass cullet into a valuable resource, free from contaminations, glass ceramics and lead glass.

Bock Energietechnik was present as specialist in electrical heating systems for the glass industry.

With extensive experience in electrical melting and glass processing, the company is active in many areas of the glass industry, such as container glass, flat glass, glass fibre and wool, and household glass.

In these industries, Bock delivers melting furnaces and feeders, especially for special applications.

Bottero Glass Technologies designs and manufactures machinery to process flat and hollow glass as well as entire production lines for laminated and float sheets.

Visitors to the flat glass, hollow glass and engineering sectors of the Bottero stand were offered extensive and transversal know-how in the world of glass, all to the benefit of the quality of the solutions offered and the service to customers.

Thankful for the “return to normality”, Bucher Emhart Glass, a division of Bucher Industries AG, was back to exhibiting as a supplier of forming machines, inspection machines, controls, and parts to the glass container industry. The company shared with visitors the end to end advancements that have helped to maintain its single source proposition for glass plant technology and support and underlined how it is continuously seeking for ways to increase automation and stabilise the manufacturing process.

Also on the Bucher Emhart stand to talk with customers and answer any questions were representatives from Ergon Meccanica, a specialist in the field of IS machine overhaul, installation and maintenance that has focused increasingly on Emhart Glass products in recent years. The two companies are strengthening their co-operation on high quality repairs and overhauls of glass forming machines, and explained how facilitating Ergon Meccanica’s access to technical information and specialists from Emhart Glass will afford customers even better results.

Bühler Leybold Optics exhibited as a provider of leading glass coating technology, with in-depth expertise in coating processes and deposition systems in the field of vacuum thin film coating.

As the central organisation for the German glass industry, Bundesverband Glasindustrie eV (BV Glas) exhibited as a representative of the environmental, economic and energy policy interests of around 80% of German glass manufacturing enterprises. Glass Worldwide is a preferred journal of BV Glas.

Bürkle was present as a specialist in the development and manufacture of lamination and coating systems for the production of technical glass, in particular functional and laminated glass. Visitors were shown that the technology is characterised by energy-efficient and flexible properties that enable a cost-effective and modern production. The range of capacity comprises designing, planning, manufacturing and commissioning, from the individual machine to the complete system solution. Electronic control and visualisation systems ensure a flexible and fully automatic production flow for the manufacture of high-quality products. Innovations showcased included the Glass Laminator IFL.

Candela promoted solutions for article inspection.

Car-Met greeted visitors to discuss the company’s range of annealing, decoration and toughening lehrs and lehrs for special uses, stackers, cross conveyors, hot glass scrapers and mould preheating ovens.

CelSian Glass & Solar displayed products and services aimed at delivering value to the glass manufacturing chain in the areas of furnace support, process optimisation and knowledge transfer. The furnace support team offered solutions for multiple challenges faced by glass furnace operations such as energy and CO2 reduction, emission reduction and increasing furnace lifetime.

CelSian showcased a number of models frequently used in its CFD software, especially NOx modelling. For process optimisation, visitors benefitted from 30+ years’ history of research within glass science and technology, while leading experts in research projects and training courses covered the challenges of today’s glass production.

Details on the CelSian Academy’s Glass Technology training courses in 2023 were also released at glasstec.

cericom showcased possibilities for glass processing with laser, including cutting, drilling, de-coating, marking, structuring, edge deletion and increasing mobile phone transmission.

Changshu Jianhua Mould Technology Co was present as a leading glass mould manufacturer in China, mainly producing glass container and tableware moulds.

Operating under the Chemetall brand, the Surface Treatment global business unit of BASF’s Coatings Division exhibited as a leading supplier of applied surface treatments and services for glass substrates

Chpolansky SAS promoted its innovations in laser cladding.

cm.project.ing exhibited as an independent glass industry consultant, offering visitors support in implementing their major industrial projects in the fields of project management and engineering.

CMS Glass Technology is a leader in the field of curved and flat glass working; the company’s technologically-advanced solutions offered to visitors included numerically-controlled machining centres, cutting tables and water-jet cutting systems.

Commersald Impianti showcased its hardfacing solutions including robot systems, innovative nozzles and remote assistance.

Condat presented a complete range of lubricants dedicated to the flat and container glass industries.

Corning Laser Technologies showcased its latest capabilities at glasstec, including demonstrations of its new glass-wafer dicing solution – a laser modification process for its CLT 400S-WD glass wafer dicing tool that can be used for small die/narrow street applications where mechanical breaking is required, and can handle up to 300mm wafers. Representatives from the company explained how CLT’s nanoPerforation process induces localised material modification rather than material removal, resulting in high-quality laser cuts suitable for fast, free-form laser cutting of complex shapes required for consumer electronics, the automotive industry and for the semiconductor/micro-fabrication sector. Corning also detailed its CLT 80G laser system which uses ultra-short laser pulses to cut glass substrates up to 2300mm x 2500mm by material separation instead of ablation, resulting in low surface roughness, higher throughput and greater break strength of the cut parts. In addition, the company highlighted its CLT 66G is a laser system for cutting and drilling tempered glass and other brittle materials. Employing axes driven by linear motors, the machine is built on a solid granite platform to ensure high stability and precision.

Cortex Glass develops and sells innovative hot end inspection, monitoring and control systems for the glass container, pharmaceutical, flaconnage and tableware industries. The company promoted its GobWatch, ISWatch, TopWatch and BlankWatch systems. The BlankWatch system measures blank side temperatures and/or gob loading parameters. The measurements are very precise and exactly timed with the IS-machine.

CTA Division Delta Thermique showcased its decorating lehrs, mainly dedicated to glass bottles printed with ceramic inks. The company’s electric lehrs offer a fine and homogeneous curing of the glass artwork over the entire width of the conveyor thanks to an efficient air circulation system and control of temperature profiles.

Cugher promoted its complete turnkey systems for screen printing on glass, including process automation and control, IR and UV dryers, automatic vision and quality control systems, handling and storage equipment. The new line configurator EVA (Extra Vision Application) was promoted.

DK Holdings presented its innovative range of diamond tooling solutions, including the Flexible Diamond Belt and the Electroflex product rang. DK Holdings continuously seeks to innovate and develop Flexible Diamond products to meet customers’ evolving demands such as reduction in production downtime as well as the increasing importance of reducing environmental impacts during the manufacturing process.

Dow launched carbon-neutral silicones for building facades verified to PAS 2060. This carbon-neutrality service can support green building designs, enhance facade sustainability and improve green building ratings.

Dr Günther Inspections presented a selection of innovative modules.

These included a new optional camera that allows the detection of glass splinters in the bottom of a piece of tableware and the software logic to separate them from dirt and dust, etc. Another option available is for the inspection of even the smallest defects on the mouth rim.

For certain articles, a precise measuring of the stress level of specific areas in the glass is important. This newly-designed software recognises higher or lower stress levels, depending on the quality requirements.

DROP AG by Hans Lüscher was present on the ESMA pavilion promoting the DROP Phoenix CtS UV-LED direct image setter that produces high-quality printing plates and offers future-proof and highly efficient imaging solutions.

DSF Refractories and Minerals was celebrating its 130th anniversary and presented visitors with developments including new refractory materials for hybrid melting and hydrogen firing, plus samples of hydrogen-fired mullite brick.

DSF’s specific areas of expertise and supply are zoned mullite regenerators, forehearth shapes including colourant forehearths, large and complex blocks and refractories for the tin bath.

The portfolio of materials includes high-fired andalusite, mullite, fused mullite, pure alumina, bonded AZS, zircon, calcium aluminate and mag-alumina spinel.

Dura Temp exhibited as a leading supplier of hot glass handling materials and quick-change parts and assemblies, providing a variety of ware handling solutions for glass containers and tableware, as well as bending and tempering applications.

The company’s high temperature products virtually eliminate damage to glass on account of thermal stress, oil absorption and abrasion.

Leading-edge materials technology is combined with a systems approach to apply the correct materials to the right applications.

Electroglass specialises in electric glass melting and conditioning.

Senior technical staff were on hand at glasstec to meet existing customers and to introduce the company’s technology, equipment and latest developments to others.

Core activities include the development, design, engineering and supply of electric glass melting and conditioning systems and related equipment.

EME GmbH reinforced its position as a leading manufacturer and supplier of batch and cullet handling equipment for the glass industry, showcasing innovations purpose-built to provide greater reliability, quality, flexibility and longevity. Offered solutions ‘Engineered for Endurance’, visitors learnt that the reliability and efficiency of EME systems and equipment are well established in the container, flat and special glass sectors worldwide and that working together with EME’s partners in the SORG Group, the company can develop comprehensive solutions for the glass manufacturing process, from the delivery of raw materials through to the start of the forming process.

Emirates Float Glass promoted its output of float glass for architectural and automotive applications. The Abu Dhabi-based company highlighted its new Vision Cool Series, which “generated great interest”, in addition to its clear

and tinted Vitralite glass; pyrolytic reflective glasses Vitracool and Vistasol; and its Emicool ST coated products for solar control.

EMS Group showcased a range including palletisers, depalletisers, robotic systems, labellers, tray formers, bottle and pallet conveyors.

Entegris featured glass handling take-out solutions, mould-top inserts and Glassmate graphite materials. Also on display was the company’s glass forming GF graphite.

Ergon Meccanica is a leader in the installation and repair of IS machines and co-exhibited with Bucher Emhart Glass.

ESMA, the European Specialist Printing Manufacturers Association and preferred partner of Glass Worldwide, exhibited together with member companies.

Their presence was marked by a showcase of the best in functional and decorative glass printing with the latest screen and digital decoration technologies.

ESMA organised its glasstec pavilion for the sixth time and companies featured included Drop, Fimor, Gallus, Global Inkjet Systems, Pröll, RUCOINX, SPS Technoscreen and Sun Chemical. Copies of Glass Worldwide’s Annual ESMA Glass Decoration 2022 publication were distributed. Visitors to the stands of ESMA and Glass Worldwide (preferred partner of ESMA and co-organiser of GlassPrint), registered their interest in the upcoming GlassPrint 2023 event, the only conference dedicated to glass decoration.

The ninth edition of this renowned educational and networking event will take place on 25–26 April 2023 in Düsseldorf.

Euromatic showcased automatic glass tubing converting equipment for ampoules, vials, cartridges and syringes.

Eurostar Concrete Technology promoted the GTM series planetary mixer.

Eurotherm promoted its power and process control solutions for improved sustainability and efficiency, including electrical boosting and melting, redundant DCS process control and turnkey projects, services and support.

Eurotherm offered support to all visitors with the transition to electrification.

Excelsius Global Services exhibited as a specialist for the heat-up, drilling and drain of glass furnaces. Services offered to visitors included heat and expansion control (including contraction measurement), controlled cool down, hold hot with and without production continuation capability, cullet fill using blowing or vibrating feeding methods, furnace tap and drain with or without water recycling and cooling, regenerator sulphate melt outs and cleaning, furnace drilling and electrode/bubbler installation and heat-up and melt-out burner/component sales and rental.

EXTRIS exhibited its screen printing mesh for the glass industry, including the SUPREX range of fabrics.

Falorni Tech – Glass Melting Technology exhibited as the industrial division of Falorni Gianfranco Srl, a historical Italian company serving the glass industry since 1958. Visitors learned that the company’s experience as a supplier of glass melting furnaces (regenerative, recuperative, oxy-fuel and oxy-fuel/electric type) enables Falorni Tech to operate not only as main contractor for EPC projects but also as a trustworthy consultant for institutional and private investors in the hollow and float glass industries.

FAMA’s wide experience in the glass container industry allowed the company to provide solutions to visitors through products and services for IS machines, feeders, glass container handling, variable equipment, maintenance, engineering services and automation.

Fenzi exhibited as a leader in the area of sealants for insulated glass units, decorative enamels for glass, mirror coatings, including those for solar thermal power and machines for digital printing on glass.

Fenzi AGT Advanced Glass Technologies, a global provider of special glass enamels and precious metal paste and now part of the Fenzi Group, promoted solutions for the automotive and industrial sectors. A recognised leader in the supply of high performance materials to the automotive glass, electronic, tableware, advanced ceramics, glass and technical glass markets, AGT launched the new laminating enamel S2-IR at glasstec. Key benefits include the removal of the need for pre-fire process, significant reduction in energy costs and time, improved printability, optical-density achieved at lower layer thickness, reduced risk of transfer S2 to S3 and robustness for simplified processing.

Ferlam promoted a range including swabs, conveyor belts, braids, narrow tapes, felts, sleeves and woven tapes.

Fermac exhibited as a designer, manufacturer and installer of equipment and complete lines for the decoration of hollow glass items and discussed with visitors the latest innovations in screen and digital printing technologies.

The product line promoted included semi-automatic and automatic machines for decorating tumblers, bottles, jugs, cups, pots, ashtrays and perfume bottles etc.

Ferro, now part of Vibrantz Technologies with Prince and Chromaflo, promoted value-add solutions for glass applications and creations. Whether coatings for architectural, automotive, container glass, or digital printing machines and inks, visitors were offered a broad array of solutions designed to their applications.

F.I.C. exhibited as a member of the Glass Service group, specialising in electric boosting design and supply. F.I.C. can assist with installing electric (super) boosting that can help to reduce carbon emissions and to maintain a furnace energy supply, should there be a shortage of natural gas in the future. F.I.C. has a very experienced team available for hot drilling and installation, if required.

Optimal boost position and amount can be simulated by Glass Service prior to installation.

Fickert + Winterling showcased flat glass rolling machines.

Fima Olimpia Fonderie promoted special cast irons for glass moulds.

Fimor, a world leader in polyurethane squeegees, displayed its Serilor line of products for most screen printing applications including window protection, anti-reflective (varnish) and details.

The company also demonstrated a variety of custom-moulded polyurethane technical parts used in the handling and protection of glass products.

Fives presented high-efficiency glass making solutions including melting, forming and conditioning technologies to increase energy efficiency, lower emissions and enhance campaign and operating life.

Visitors learned about innovative technologies for greener glass manufacturing from fully electric furnaces to advanced forehearth design, including all electric melting solutions, hybrid solutions, electric forehearths and optimised design.

Flammatec (FT) is part of the Glass Service group and a leading supplier of advanced burner technology for glass furnaces. Innovations on show included the new Hydrogen Carbon Free burner, introduced recently in response to environmental challenges to reduce CO2 footprints. FT burners are suitable for all types of regenerative furnaces and produce a high luminous flame with under-port and side-port installations. They are suitable for oil, gas and dual fuel, creating low NOx through efficient heat transfer, resulting in faster batch melting. FT also provides an oxygen burner and supplies a complete range of advanced combustion equipment.

Flokontrol Industrial Automation offered visitors intimate knowledge and experience of pneumatic, robotic, electromechanical, hydraulic and electric control systems that enable the company to provide tailor-made robotic solutions.

Innovations promoted included I.S. machine swabbing robot, robotic palletising systems, robotic case packaging systems, conveyor and carrying systems, automatic guided vehicles and robotic vision systems.

The company’s ‘BRUSH & SPRAY System Together’ was presented as the new generation swabbing robot.

Fonderie Bartalesi highlighted bronze alloys for moulds for the production of glass bottles and jars.

Forglass, a specialist in the design and construction of glass furnaces and batch plants, showcased innovative solutions, inventions and concepts for lowering emissions and energy consumption. As an added attraction, Marek Kaminski (Polish polar explorer, Guinness World Record holder, successful entrepreneur and educator) was present.

Forma Glas exhibited as an innovative manufacturer of glass production machines for stemware, tumblers and press articles from Austria. Visitors learned about Forma’s expertise in engineering, construction, research, consulting and know-how in the field of production lines, glass processing machines and cold processing machines.

Fosbel promoted its technology, expertise and materials to increase productivity and extend the life of furnaces in glass and other industries. Its broad range of preventative maintenance and remedial repair services include ceramic welding, Fosbel’s innovative refractory repair performed at operating temperature, as well as condition monitoring, inspections, rebricking/rebuilding and other innovative hot repair technologies.

Fuchs showcased its extensive VITROLIS product range covering moulding, shear, synthetic machine oils, delivery lubricants and coatings for the container manufacturing industry, with cutting, grinding and bevelling fluids for the float glass industry and H1-approved lubricants for the vial forming and pharmaceutical industry.

futronic, celebrating its 50th anniversary, showed a selection of innovative products. The focus was on the FMT24S (Flexible Modular Timing System), the high-end control system for all sequences and processes on an IS machine. futronic’s experts demonstrated the FMT24S on an FMT Trainer designed to provide essential training and continue professional development – and which also serves as a spare parts container for components. The Swab Cycle Monitoring System (SCMS) was also on display on the training section.

The SCMS monitors swab cycles automatically and outputs visual and acoustic warnings indicating when, and on which section, the next cycle is due. futronic’s new Vacuum Process Control System (VPC), which makes processes visible in the vacuum cycles by recording pressure curves and errors precisely, also made its debut at glasstec.

The system allows manufacturing problems to be detected before they have a chance to occur.

Gallus presented its Screeny C-Line and G-Line, setting standards on cost-effectiveness and production reliability for decorating hollow glass and containers using industrial screen printing. Gallus combines Screeny screen printing plates, a computer-to-screen UV-LED imagesetter, a development system and an ingenious frame system into a unique complete solution, leading to reproducible printing results in just a few simple steps.

GEA presented emission reduction technologies, in particular the capture of carbon dioxide from waste gases through CO2 scrubbing; solutions that can significantly help plant operators reduce environmentally harmful emissions, improve their energy efficiency and facilitate the path to carbon neutral production. Visitors learnt that GEA offers small and medium-sized CO2 capture plants with great flexibility, allowing customers to produce CO2 with varying exhaust gas compositions; this includes solutions using carbonates, amines or ammonia.

Giancarlo Perego displayed moulds and mould technology for the glass industry, as well as highlighting how the company has actively invested in machinery and technology in recent years.

GIMAV, the Association of Italian manufacturers and suppliers of machinery, equipment and special products for glass processing was represented at glasstec. An impressive number of member companies participated.

Online since 2000 and counting over 360,000 visitors/month, glassglobal.com is the world’s largest portal for the international glass industry and preferred partner of Glass Worldwide.

The group’s glass experts were present at glasstec to provide sophisticated services to all segments of glassmaking, covering everything from raw materials to production and processing. Features include a comprehensive database, a trade market for machines and glass, an expert job market, project information from greenfield to repair, together with technical consultancy covering marketing, research and technical trends.

GlassFORM.ai offered visitors quality control combined with automatic machine adjustment, leading to an increase in overall productivity through reduction of wastage, improvement of glass, glass weight reduction and optimisation of the production processes

GlasStress promoted its scattered light polariscopes for stress measurement in architectural glass, automotive glazing and solar panels, as well as its automatic transmission polariscopes for stress measurement in bottles, drinking glasses, tubes and tableware.

Glass Service from Czech Republic is a specialist in glass melting expertise and advanced laboratory technologies and presented the know-how and simulation software to help manufacturers select the most energy/cost-efficient way to melt glass.

This expertise and service is supported by the company’s popular GS GFM simulation software. GS’ Expert System III (ESIII) has been rolled out worldwide to glass producers. ESIII dynamically controls furnace operation by means of a proven Model-based Predictive Control (MPC) system which utilises the energy source that is most cost-efficient to melt glass. ESIII not only brings down energy costs, it also reduces carbon.

Also part of the Glass Service group, F.I.C. and FlammaTec exhibited at glasstec as well.

Experts from Italy’s Glass Service Srl answered customers’ questions about the production of technologically advanced furnaces for neutral borosilicate glass production and were on hand with a long reference list of plants that the company has built.

Visitors to the stand heard how Glass Service studies, tests and applies new solutions to its systems, and were informed about the cost-saving advantages of the oxy-gas combustion furnaces and electric boosters that it supplies.

Also discussed were mixed melt furnaces: by integrating oxy-gas combustion systems and the extended application of electric booster systems on the bottom of the furnace, Glass Service has created more than 20 mixed melt furnaces for producing hydrolytic class I neutral glass for pharmaceutical applications.

Advantages include a very low gas consumption, and consequently, a very low CO2 footprint, whilst maintaining the high flexibility and production quality guaranteed by cross fired furnaces with oxy-gas combustion. According to members of the team, Glass Service is actively working on channels and distributor interventions to improve energy balance and reduce CO2 emissions. Glass Service has also started testing H2–O2 burners of its own design.

Glassworks Hounsell exhibited batch charging (including wetting) equipment for all types of glass and furnace types, as well as tin oxide refractory electrodes and relevant connectors for lead and special glass production.

With machines supplied throughout the world, the company remains at the forefront of design, manufacture and installation of parts, individual machines and furnace management systems

Glaston shared some of the latest developments from its efforts to help shape the sustainable future of glass. To automate the flat glass tempering process the company has devised an online stress calculation solution using measured process data to calculate temperature and stress distribution during quenching. Glaston also introduced its White Haze Scanner – the first AI-based solution to provide a high-quality visual indication of an unacceptable white haze on processed glass and instantly notify users.

Visitors to the stand learned about the Glaston ProL flat glass lamination line, and how its convection heating chamber makes switching between glass types and different glass sandwiches even easier. To achieve a higher degree of automation, Glaston’s lamination process autopilot enables the furnace to ‘learn’ the most optimal way to run. glasstec attendees interested in insulating glass benefitted from hearing about the Glaston MULTI’ARRISSER: a 3-in-1 solution for economical glass edge arrissing, flat edge arrissing and corner dubbing that has a maximum arrissing speed of 60m/min, making it the world’s fastest single-head machine.

Other solutions featured were Glaston’s TPS (Thermo Plastic Spacer material) which can be applied directly onto the glass plate, eliminating the need to stock different spacer profiles and connectors; the CHAMP EVO grinding machine for automotive glass pre-processing; the HYPERFEX system for glass edge grinding; and the new Glaston MATRIX EVO automatic bending furnace for perfectly curved automotive windscreens and sunroofs.

Global Combustion Systems promoted NOx reduction by auxiliary injection, as well as burners for all furnace types (gas, oil and oxygen), complete fuel control systems (gas, oil and oxygen), furnace control systems, engineered system solutions and after sales support.

Global Inkjet Systems (GIS) exhibited as a leading developer of industrial inkjet software, drive electronics and ink/fluid delivery system components – including different flow rates as required. GIS production-ready, field-proven products are designed to work reliably 24/7 in industrial settings for key glass industrial printing applications including flat, container, solar and more.

Innovations promoted included the advanced Atlas IQ Tools image optimisation software for printing on glass to help improve image quality, including stitching strategies, nozzle-out compensation and rotation correction.

GIS also offers a customisable user interface and the company’s technology can be implemented in many different system configurations – XY scanning, single pass and custom-configured systems.

Grafotec promoted its high tech innovations for the glass industry as a leading specialist for separator application systems.

The company’s separator application systems are specifically customised to match perfectly into any existing flat, float or automotive glass production line, anywhere in the world.

Innovations included AP TWIN, a high quality nozzle system for two different separator agents during the production process.

Graphoidal Developments is a leading designer and manufacturer of advanced lubrication and coating technology to the glass container and tableware industries.

Visitors were offered expertise in precise pumping, control of mixing, dosing and spraying of the lubricants and coatings which form a vital part of the glass production process, both in hot end and cold end areas.

Grenzebach Maschinenbau exhibited as a manufacturer of float glass production equipment. The company presented its new annealing lehr, which offers precisely adapted cooling capacity, a flexible annealing point and significantly reduced energy consumption. Visitors could also preview Grenzebach’s innovative dross boxwith motor-adjustable lift-out curve, optimised atmosphere separation and temperature distribution, as well as intuitive control and improved maintenance options. In addition, the manufacturer showcased its new conveyor technology for optimised glass production with direct drive, a reduced number of components and simpler access to key components.

In mid-2022 Grenzebach partnered with SORG for the provision of engineering services related to glass production and the development of turnkey projects.

At glasstec the two companies presented their services “shoulder to shoulder” at neighbouring booths. Grenzebach Envelon – the business offshoot brand for solar-active building façades/building-integrated photovoltaic systems exhibited in a separate hall and Vice President Sales and Business Development, Jochen Weick, gave a presentation on “Glass in active building façades” on the opening day of glasstec.

The joint Grünig-Interscreen AG/SignTronic AG display re-emphasised the ‘Simplify Screen Printing’ theme and how automated screen production with higher quality and cost reduction is also a top issue and a great need in the field of screen printing on glass. Visitors learned how automated screen-making equipment can modernise and optimise operations.

Guardian Glass displayed a number of its innovative products and devoted a section of its stand to a ‘library’ of coated glass samples, which visitors were encouraged to view. Available for European customers was SunGuard eXtraSelective SNX 70, offering “outstanding solar control and light transmission approaching 70%.”

For the Africa & Middle East region, Guardian Glass’ SunGuard SuperNeutral SN Carbon 50 T has been developed to answer growing demand for performance glass with a stylish, neutral grey appearance. New for North America is SunGuard SNR 50, designed to help create bright, inviting spaces by combining crisp neutrality on the exterior with reduced 0.25 solar heat gain and 48% light transmission on the interior.

The company also introduced its new 0.6% reflectivity Clarity Neutral glass, which offers the highest transparency of any Guardian Glass product to date by reducing glare and bluish reflections to provide truer, more natural views. Appearing “almost invisible”, the new glass reduces undesirable light reflection and refraction across more angles and light frequencies, even in low or diffused background light conditions. It also benefits from lower haze and colour shift after being heat treated.

In addition, Guardian announced its new Resource Hub offering both customers and the wider glass community a wealth of technical information, and featuring a new 24/7 Customer Service Portal to streamline ordering and communications.

HEGLA focused its efforts on showing visitors solutions for creating sustainable added value, incorporating an elevated walkway into its stand area to facilitate viewing of its running machines and systems for processing flat glass.

The equipment provider explained how its laser diode technology shortens heating time and increases value creation in LSG cutting.

There was also a first-showing of its vertical remnant system for reducing glass waste. HEGLA-HANIC provided insight into its redeveloped next-generation ERP [enterprise resource planning] software system, which can integrate a wide range of essential programs as well as offering options for add-ons such as financial bookkeeping or control via a Microsoft platform.

HEGLA boraident displayed samples of its bird protection glass, antibacterial panes, heatable glass and RF-transparent IG offerings to illustrate how standard glass can be finished by removing or transforming the functional layer, or via non-destructive printing with its Laserbird technology. Known for its convection technology and closely-controllable heating zones, HEGLA TaiFin detailed the qualities of its tempering furnace and explained how the combined benefits of bed optimisation, automated batch creation and ‘de-batching’ can increase total throughput and save energy. HEGLA New Technology took visitors though its Shop-Floor app, which provides services such as consolidating machines and systems’ maintenance requirements, assigning work to employees, and location-independent product tracking.

Heraeus promoted precious metal compounds and a product range comprising semi-finished products and massive components for glassmaking, as well as precious metal preparations for the decoration of glass.

Heye International was present as one of the foremost suppliers of production technology, high performance equipment and know-how for the container glass industry worldwide.

The three brands promoted at glasstec, HiPERFORM, HiSHIELD and HiTRUST, form the Heye Smart Plant portfolio, addressing the glass industry’s hot end, cold end and service requirements.

HFT exhibited as a leading, design-build EPC (engineering, procurement, and construction) contractor focused on delivering reliable and transparent single-source project solutions from greenfield, new-build facilities to operational support and maintenance.

Headquartered in Pittsburgh, USA – and with regional offices in the UK, China, the Philippines, Singapore and St. Croix – HFT employs engineering and construction professionals and craftsmen around the world. The company has design-built 300+ production lines throughout 47 countries and celebrated its 75th anniversary at glasstec

HORN Glass Industries promoted innovations such as E-fusion power boosting and a new glass level measurement with radar beams alongside its wide range of experience in the design, manufacture and supply of different furnace types, such as regenerative and recuperative continuous tank furnaces, float furnaces, electrical tanks, pot furnaces, day tanks, electrical tank furnaces for domestic and lighting ware, tableware, containers, technical glassware and sheet glass etc.

Utility equipment includes combustion systems, control and safety equipment, electrical boosting and mixing systems.

Also offered are forehearth systems, supply stations for oil, gas, oxygen and water, regenerative and recuperative burner systems, combustion equipment, boosting systems and process control systems.

Partner company JSJ Jodeit was also present as an expert in all-electrical and specialised furnaces.

Hotwork International exhibited its solutions for combustion technology for air- and oxygen-fired furnaces, preheating of gas and oxygen, high energy efficiency, low NOx and emission control, electric melting technology and furnace draining and heat-up.

Hunprenco highlighted its position as a leading manufacturer of plungers and cooling tubes for the glass container industry.

A wide range of machine parts are also manufactured to the highest quality, including adaptors, split collars, Vertiflow plates, mould arm inserts, piston sleeves etc. With a comprehensive range of four- and five-axis CNC milling, drilling and turning machinery, as well as manual equipment, the majority of customer requirements can be satisfied.

Constant investment in high technology machinery upholds the company as a leader in this competitive market.

HyGear promoted technologies that could help visitors’ businesses by supplying cost-effective and low carbon emission gases through on-site gas generation and recycling.

IfG Glastechnik showcased machinery to apply separating powder and other technical particulates to all types of sheet glass and ultrasonic wet spray glass coating systems.

ilis presented the company’s latest developments in the areas of measurement of residual stresses with StrainScope, measurement and control of the glass colour with Chroma and batch calculation and glass development with BatchMaker.

Imaca offered its complete range of products and equipment for the hot end and cold end for glass container manufacture. Products on show included hot end coating chemicals and equipment, cold end chemicals and equipment and lubricants.

Industrie Fonderie Valdelsane specialises in the production of cast iron moulds for the glass industry, developing processes and technology orientated towards the products required.

Inkcups demonstrated the MagiCoat Glass Pre-Treatment System, utilising a flame treatment system along with a spraying system for spray-on primers. This system boasts eight stations that rotate individually while going through the system. Each item is flame-treated to eliminate debris and coatings that inhibit adhesion. The system also offers variable mist settings for a wide range of surfaces.

The Helix Digital Cylinder Printer showed its ability to print full-colour, high quality images on drinkware, especially when leveraging Inkcups’ specialised helical software for print techniques such as mirror print. At glasstec, the Helix was equipped with Transparent Pin Curing (TPC).

intco promoted its specialist service for glass manufacturing companies, involving the procurement of refractory materials for glass furnaces.

The entire process is monitored in detail and key figures are carefully recorded throughout the whole production period.

Interglass exhibited as a leading developer, manufacturer and supplier of specialty lubricants for the global glass industry. Innovations promoted included new swabbing compounds with ‘Smart Solid Technology’.

The company was founded in 1992 and is part of the Interlub Group, a leading specialty lubrication company that develops and manufactures tribological industrial applications.

Intermolde met clients and friends on its stand, showing moulds and accessories that permit efficient glass production. The full product portfolio was presented, including blow moulds, bottom plates, blank moulds, baffles and baffle inserts, funnels, blow heads and blow head tubes, neck rings, guide rings, thimbles, plungers, coolers, take-out tongs and distributor plates.

IPROTec GmbH exhibited as a young, rising company in the industry of special purpose machine-building with worldwide operations.

The firm specialises in the development, construction, planning, manufacture, assembly and commissioning of machines and systems that are designed optimally under holistic consideration of the customer’s specific environment and with the greatest possible expertise.

Visitors learnt that IPROTec’s competence lies above all in classical special purpose machine-building.

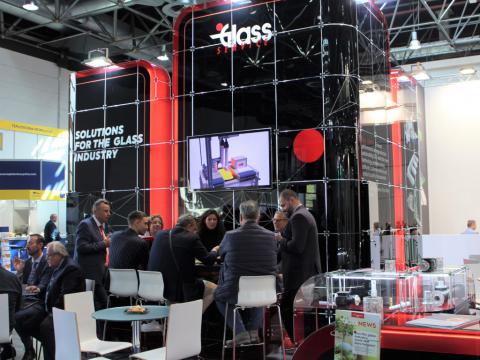

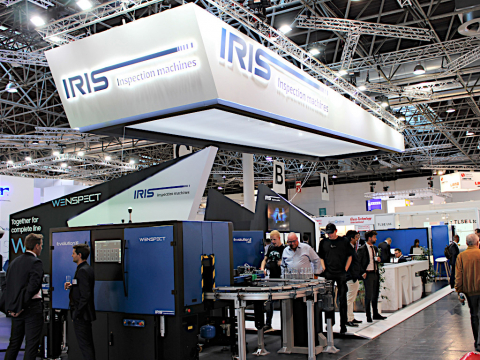

IRIS Inspection machines introduced two major innovations: the new Evolution NEO AI inspection machine based on artificial intelligence and iBot, the intelligent assistant for optimised productivity. IRIS was present as a leading designer, developer and manufacturer of intelligent inspection solutions for glass containers.

glasstec attendees learned about the company’s precise and innovative inspection machines with reduced dependence on human factor for increased productivity, quality and efficiency. Innovations include the EVOLUTION machine range with NEO intelligence based on an innovative defect approach that relates to defect identification, as well as the creation of statistics by defect type.

Local trend analyses are produced on the machine, with information presented in a user-friendly format.

ISIMAT, a subsidiary of the KURZ Group, shared with visitors innovative decoration solutions with metallic effects and brilliant colours for glasses, bottles, and flacons under the motto ‘Making your glass first class.’ Innovations included ISIMAT’s I-Series machine portfolio, offering the ability to combine different decoration technologies such as screen printing, digital printing and different kinds of foiling solutions in one machine pass, thereby extending the flexibility of a hybrid decoration approach. Within the I-Series ISIMAT offers users metallisation technologies such as inLINE FOILING, hot-stamping or precious metal inks for finishing and upgrading end products.

ISRA VISION demonstrated its unique, innovative and comprehensive portfolio of products for optical inspection of glass products, suited for almost all production steps in the glass industry, from inspecting the glass ribbon through to the thinnest display glass and from processing sheet glass to business intelligence.

Italcarrelli presented its most recent self-propelled transporters for the flat glass industry and numerous other projects developed, including some prestigious AGVs already in operation in many glass manufacturing and processing facilities around the world.

Visitors had the opportunity to see a demo of an AGV transporter for the handling of flat glass on racks, focusing on the loading / unloading of a rack between different stations fully autonomously.

Keraglass displayed high-tech solutions for tempering, lamination and decoration on glass.

Kissel + Wolf highlighted screen-making chemicals, flock adhesives, resists and coatings for surface finishing by KIWO. Products on show included quality emulsions, sputter resists, etching resists, flock adhesives, sandblasting resists and liquid protection films. The selective sputter coating for decorative and functional applications on architectural glass attracted great interest.

Koenig & Bauer Kammann GmbH presented a wide range of machine solutions for screen and digital printing.

Visitors to the stand learnt that the addition of digital alongside screen technology in the same portfolio allows Koenig & Bauer Kammann to offer more solutions to customers who recognise the possibilities of combined machines and equipment that can be used for screen and digital decoration.

KTG Engineering, part of the TECO Group, promoted such products and services as electrode holders, boost, bubbler, level control and controllable drain systems, spy hole covers, screw batch chargers, molybdenum/tin oxide electrodes and installation services.

LAT Maschinen- und Antriebstechnik GmbH & Co.KG (Himmel technologies) promoted the benefits of the new Servoelectric Stacker ES854, including all three axes operating in a closed-loop ‘Speed- and Position Control-Circuit’; automatic synchronisation of the cross travel speed to cross conveyor; sensible interlocking in software (programmable) between all three axes; infinitely adjustable travel speeds and positions; infinite programming of accelerating and slowing down ramps for all three axes; up to 20 cycles per minute; efficient and reliable cooling with heat exchanger; and selectable staggered stacking also in home position.

Lattimer exhibited as a market leader in the design and manufacture of high quality IS variable equipment for the glass container forming industry.

LiSEC exhibited as a producer of machines for flat glass processing and finishing.

The company’s sales team and product specialists promoted its motto ‘all.in.one:solutions’ and demonstrated the Austrian-manufactured machines, as well as taking visitors through LiSEC’s latest technical innovations, software solutions and services.

Innovations at glasstec included the KSD – vertical edge seaming and grinding machine with LiTEC slider technology, the DSC-A high performance machine for cutting flat glass automatically and the RHV automatic vertical loading and unloading via robot.

Lizmontagens Group promoted its complete scope of services for the glass industry, including the construction and repair of industrial furnaces, total refractory installation, steelwork installation and manufacturing, project management of turnkey projects, procurement and supply of refractory and insulating materials, furnace cool down control, hot sealing and insulation installation and technical appraisals.

Luben Glass promoted mechanical components, plants and chemical products for the hollow glass industry.

Lüscher Technologies demonstrated its ultra-compact ‘JetScreen! CS’ computer-to-screen system for the high-end production of screen printing stencils.

The company showed how, combined with its in-house X!Tend software – which adjusts the size of graphic elements in screen emulsions, capillary films and photoresists (positive or negative) to compensate for light diffusion, diffraction and other physical phenomena – optimal image results can be achieved from processing TIFF data.

LWN Lufttechnik used glasstec to celebrate 25 years as a leading supplier of innovative cooling systems for the glass industry.

Highlights included cooling systems for IS machines, glass furnaces and glass processing, as well as system components and automatic control systems.

The team offered expertise in consultation and needs analysis, planning, preparation, production and assembly.

Magneco/Metrel’s unique colloidal silica-bonded monolithic refractory products offered visitors an alternative to traditional refractory technology used in the glass furnace. Metpump-brand products can be used in different applications for cold and hot repairs, in emergencies and for scheduled repair projects.

manufactIS GmbH, a ROSS subsidiary, promoted complete IS machine support service, taking care of consulting, development, design, spare parts, and on-site service.

Mappi, a designer and manufacturer of high quality tempering systems, presented the MTH, a new furnace designed for those who have to manage large load volumes and process very large slabs without sacrificing quality, flexibility or energy savings.

Ink manufacturer Marabu introduced its new offering for digitally-printing three-dimensional effects on glass: Mara Shape DUV-HBV High Build Varnish.

The company explained how, by enabling multi-layered and consistently sharp reliefs to be produced, the process is suitable for printing ultrafine haptic details, even on convex or concave geometries as well as higher and thicker graphic elements.

As a bonus the varnish is recyclable – oxidising without any residue. Marabu also promoted its UV-curable Ultra Glass UVGL screen printing ink system for creating haptic effects and, when combined with hot foil embossing, high-gloss metallic finishes.

Offering visitors myriad options for digital-/screen-/pad-printing on glass, and displaying numerous examples of printed products, Marabu continued to champion its organic UV-curable inks as an effective and energy-efficient alternative to ceramic glass printing inks.

Marposs showed a wide range of gauging solutions for dimensional and geometric inspection of glass products. Highlights included the flexible Visiquick machine for dimensional and geometric inspection of glass containers on a sample basis. A new way of shaped glass non-contact assessment was also presented. The displayed demo bench showed a robotised system of measuring curved glass thanks to two different technologies built-in: laser beam for borders evaluation and chromatic confocal for surfaces, even multilayer, inspection (thickness, roughness, shaping). The arm moves the sensors head which collects continuously measurements along its path without any stop.

The analysing central unit gathers data and matches the measurements with the thresholds set in the recipe punctually, to provide the final total qualitative evaluation. The strengths of this innovative system are oriented to increasing productivity, flexibility and speed, without compromising the accuracy traditionally identified with Marposs’ solutions.

The new technical approach is dedicated to small parts as well as to large parts (such as windshields) and is made available as turnkey automation or just equipment of measuring to be implemented in a third machine. Industries that take advantage of this cutting-edge technology are those manufacturing or processing complex shape glasses, such as automotive, avionics, furnishing and medical.

Merkle International, a leading supplier of suspended refractory systems and related furnace equipment, promoted suspended backwalls, tin bath roofs and other furnace components, as well as blanket batch chargers.

Mersen offered proven solutions for hot glass handling in graphite and carbon/carbon composites. Under the Cerberite brand, the company has developed a complete range of systems and solutions dedicated to hollow glass production lines.

Monofrax promoted its diversified line of fused cast refractories.

Motim Fused Cast Refractories was present as a leading producer of fused cast AZS and alumina refractories and refractory castables. In the glass industry, the company’s blocks are used in all melting furnace types for container, float, tableware and special glass production.

MSK Covertech Group exhibited as a market leader in the field of cold end equipment.

With innovative solutions for conveying systems and palletising systems up to packaging systems, the company offered visitors a variety of complete, fully automatic systems covering cold end technology, bottle conveying, palletising, packaging, handling and software.

A highlight at glasstec was experiencing MSK technology in virtual reality.

MT Forni Industriali demonstrated its specialisation in glass melting furnaces, annealing and decoration lehrs and bending furnaces.

Nirox Optoelectrics showcased optical measurement sensors and systems for glass pharmaceutical primary packaging.

NOGRID promoted its meshless flow simulation software, support and service. Technology includes CFD (computational fluid dynamics) software for the simulation of flows, NOGRID points and a second innovative CFD software product on the market, NOGRID pointsBlow, which is the only software worldwide that is able to simulate the process of container glass forming in a completely professional way by showing the results in full 3D. In addition to software products, NOGRID offers a variety of services in the area of modelling for the simulation of flows.

Novaxion offered leading equipment and software in the field of automatic glass production and machine swabbing.

Visitors discovered the new NX-VR-300 swabbing robot that mounts on the valve blocks of all IS machines and provides mould closed and neck ring automatic swabbing within the same section cycle.

NTE-Process showcased conveying, mixing, dosing and automation systems. Innovations include a blender transporter, baghouse and ESP dust handling and raw material handling.

The OCMI Group produces and supplies solutions for the production of tubular glass pharmaceutical and cosmetic containers. Innovations on show included the new FLA18-9 machine, engineered and manufactured to produce parental glass containers. Visitors learned that cutting edge technology, innovation, quality and the machine’s features are making the FLA18-19 a new point of reference in the panorama of the pharmaceutical industry.

Olimerk, a sister company of Olivotto Glass Technologies, promoted quality moulds and equipment for tableware production, including press blow, press, stemware, spinning and twin table.

Olivotto Glass Technologies presented its machinery, systems and solutions to visitors, including landmarks in press and blow production.

Innovations promoted included machine sections available in pneumatic or servo configuration with speed range up to 170 pieces per minute, high repeatability heads mechanism movements, easy and quick job change and energy-saving configurations.

OGT also promoted its ‘Earth Value’ project dedicated to environmental protection.

OMCO promoted a complete range of mould parts for glass container production.

Visitors were offered equipment for any shape in a wide variety of quality cast irons or aluminium bronze, using various welding techniques to increase mould life.

OMS Group (Officina Meccanica Sestese) displayed its complete range of end of the line packaging machines, including strapping, stretch and shrink hooding.

OMSO showcased the SB021 screen printing machine alongside a complete range of decorating machines.

SB021 fulfils the market need for modern machines that are easy to use and attentive to today’s hot topics: reduced energy consumption and lowered emissions.

The machine is equipped with a high-efficiency motor that reduces the energy requirement for its operation by 70%.

Other innovations included Servobottle, the automatic screen printing machine for printing up to 10 colours on glass containers; NovaxM, an automatic single-station modular screen printing machine for decorating bottles; Imprex, an automatic screen printing machine for printing 2–6 colours on cylindrical, elliptic and flat containers; the compact Servobottle8 which offers a maximum of four screen-printed colours with the same qualities as Servobottle but at a lower cost; and the Servojet solution for digitally-printing up to seven colours on bottles, containers and jars.

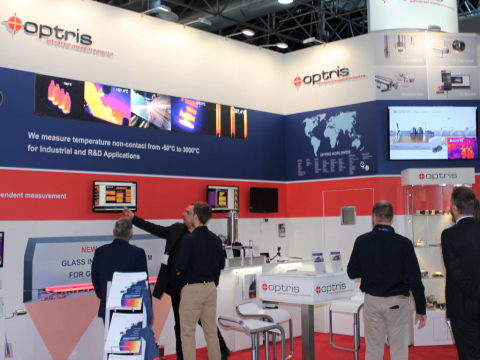

Optris GmbH exhibited its wide range of non-contact temperature measurement through infrared radiation including the Optris Bottom up glass inspection system for glass tempering plants that offers a new approach to temperature measurement in the production of low-e glass.

Low emissivity glass poses a major challenge for infrared devices which traditionally measure the glass temperature from above when the panes are moved out of the furnace during production.

The new Bottom up glass inspection system solves this problem by having two infrared imagers installed underneath the tempering line to measure the temperature on the non-coated high emissivityside of the glass.

Ormo Print presented sol gel coatings for surface finishing and various inks for digital printing.

PaneraTech revealed the new Digital Furnace Monitoring (DFM) programme to monitor and nurture furnaces from the cradle to grave for the longest campaign life they can experience.

Other solutions promoted included SmartMelter, proven as an accurate method of refractory inspection and overall furnace health management. Using real data from sensors that measure actual wall thickness, PaneraTech’s complete furnace management solution provides valuable insights for furnace life optimisation.

Visitors learned about SmartMelter features such as mapping wall thickness below the glass level; detecting glass infiltration into the insulation to eliminate glass leak risk; determining the pace of erosion for optimal overcoat, minor and major rebuilds; keeping comprehensive furnace maintenance records including other inspection records, endoscopic images and pictures; lowering insurance premiums; and enabling implementation of standard inspection and furnace management policies across multiple plants.

Parkinson-Spencer Refractories combines refractory manufacturing with engineered solutions and offered visitors the complete solution to the glass conditioning process.

PSR is a leading supplier of feeder expendables and forehearth and distributor refractories.

The company’s expendable refractories provide the confidence and reliability required for modern container glass manufacturing. Innovations promoted included channel blocks, the PSR System 500 forehearth and PSR’s Cord Dispersal Stirrer System.

The company promoted its design and supply of refractories and engineered equipment for the glass conditioning process.

PD Refractories offered visitors a broad, high-quality and innovative product portfolio, encompassing the entire range of hydraulically and isostatically pressed, hand-shaped, vibration, slip or melt-cast refractory materials as well as unshaped refractory products.

Pennekamp is a leading manufacturer of hot end automation systems, lehrs and cold end coating equipment. Included in the product range promoted at glasstec were high performance ware transfers; special cross conveyors, also available in water-cooled versions; various types of servo lehr stackers (with one, two, three and four axes); energy-saving lehrs, including annealing lehrs for containers and tableware; decorating and toughening lehrs; flat glass lehrs for automotive and architectural float glasses, display TFT glass, patterned and solar glass; specialty lehrs; and cold end coating and dosing units.

Pennine Industrial Equipment showcased inverted tooth silent chain for conveying applications within the glass industry.

Visitors were presented with a patent pending skeleton link chain.

The original range of single pin chains is offered with the largest selection of pinhead protectors including the first and original head protector, all-steel options and the new Swift-Link. To complement this range, Pennine also offers Calibre 2 Pin chain in both ½in and 1in pitch, a solution to rapid chain elongation on modern high speed production lines.

Pennine can also offer chains in stainless steel to help prevent bottom defects caused by oxidisation or thermal shock; and castle link, which provides a smaller contact area. Custom chains can be designed and made for the most demanding applications.

Manufacturing glass under the Pilkington brand, NSG Group’s stand was frequently visited by glasstec attendees photographing its striking optical illusion-esque colour-change display of Pilkington Optiwhite.

Also eye-catching was the example of ‘ElectroglaZ’ created especially for the stand by UK touchscreen and glass processing specialist Zytronic, using Power-Tap (P-Tap) wireless power technology from product design studio Cohda in conjunction with NSG TEC electrically-conductive glass. The minimalist ‘floating’ audio speakers provided ample sound and wouldn’t look amiss in a luxury tech-focused residence. Other well-curated exhibits included Pilkington AviSafe, featuring a just-visible patterned UV-enhanced coating that deters birdstrikes by disrupting reflections and appearing as a dense barrier to avian eyesight; SenseComfort – an insulating glass exhibited in a unit with a special sensor developed by Netherlands-based start-up company PHYSEE that measures incoming light intensity and solar radiation, and was shown with a fitted blind that opens/closes accordingly.

There were blue, grey and bronze examples of Pilkington Mirropane Chrome Plus corrosion-resistant mirrors – the colour comes from the glass, not a coating – and the unveiling of HeatComfort glass, which emitted pleasing warmth to chilly hands when voltage was applied to its electrically-conductive NSG TEC coating. When incorporated into an insulating glass unit, the heat flow can be directed into the living space, and the technology can even be employed so that windows become the sole source of heat for a building, Glass Worldwide was told. NSG also previewed Pilkington OptiView anti-reflective glass (“We are going to think about a ‘more cool’ name [...] as the product doesn’t exist yet,” confided Jolanta Lessig from NSG Group), which employs an anti-reflective coating on surface one, in combination with an extra clear low iron substrate, to improve the appearance of a digitally printed picture on surface two of the glass. The product was illustrated on NSG’s stand as the glass case for a museum exhibit.

Pietro Bonaiti exhibited as a specialist in the production of conveyor belts for annealing and decorating.

Pneumofore, a leading supplier of centralised vacuum and compressed air systems for the glass industry, presented itself with a new open-view booth concept that welcomed visitors and encouraged them to discover the core of Pneumofore Rotary Vane technology, products and the company’s underlying values.

With the support of a highly qualified team, visitors enjoyed high-level conversations on how to achieve high energy savings, constant performance and the lowest life cycle cost on the market.

The spotlight was on the UV24 VS vacuum pump – presented at glasstec in its Variable Speed version – which generated great interest.

Precitec Optronik GmbH, a German manufacturer of highly innovative sensors and optical probes, promoted its CHRocodile product line for contact-free thickness and distance measurements. Precitec’s contact-free sensor systems can measure the thickness and topography of any colour or surface, e.g. container glass in stop-and-rotate machines; wall thickness of hot quartz pipes; circular deviations of bottles; and PVB foils found in HUD windshield films. The products deliver in process, inline and offline measurements with high precision and ultra-fast measuring speed on all materials and measurement ranges from micro- to centimetres.

Pro-Sight Vision highlighted its position as a designer and manufacturer of inspection machines and glass container handling equipment. New innovations included the Sink and Bulge machine which uses cameras to measure the flatness of a label panel area.

The new Universal Finish Inspector System was also presented as a powerful offline quality control machine which is able to measure a wide range of critical dimensions and angles from the neck line up to the sealing surface, along with the new feature of guide plate seam defect inspection and measurement.

Pro-Sight has also developed the Dimensional Gauging Machine, a semi-offline machine that uses mould number reading to remove one of each mould number from the cold end production line every hour.

Pröll exhibited its range of custom-made chemical products for coating and decorating glass. Visitors could learn more about NoriGlass OR (outdoor resistant), a new glossy silicone free two-component glass screen printing enamel ink developed for the second surface decoration of glass, particularly for backlit displays of vending or ticket machines.

Also featured was NoriGlass TP: an organic enamel screen printing ink suitable for touch switches and the backlit displays of smart phones and tablet displays; Aqua-Temp SIG: a water-based stoving lacquer that can be used for decorating the displays of household appliances; and Protective Lacquer L 68742: a final overprinting lacquer that shows excellent scratch resistance.

In addition, Pröll showcased its TF-QuickChange Screen System for printing thermo plastic inks on glass hollowware.

Pyrotek’s glass solutions team offered visitors ideas to enhance manufacturing operations and improve overall performance. The company offers an entire line of custom-made products.

PVAG water systems GmbH was present as an innovative and reliable partner for dosing technology and water treatment in the glass industry. Services promoted included supply and engineer dosing systems in the fields of shear and scoop spray, machine lubrication and cold/hot end tempering. Visitors were informed about closed loop, customised programming solutions via digital twin, water system design, predictive maintenance measures and optimisation of process controls.

Quantum Engineered Products, part of the Rondot Group, attended glasstec 2022 to reinforce its commitment to the intelligent engineering of glass container forming systems. Quantum has been providing forming solutions to the worldwide glass container industry since 1976. The company’s forming system provides a combination of hardware and software across all forming processes.

Quantum’s area of expertise is the Blank Side Forming Processes and related hardware and software, such as Quantum’s TOTAL FORMING ANALYSIS – (TFA) process monitoring and gob weight control. Using the Cylinder Performance Monitoring System (CPMS) feature of the TWT allows the operator to see inside the initial forming cycle of the container manufacturing process and provides a variety of production benefits.