AGC Develops Digital Twin Technology for Glass Melting

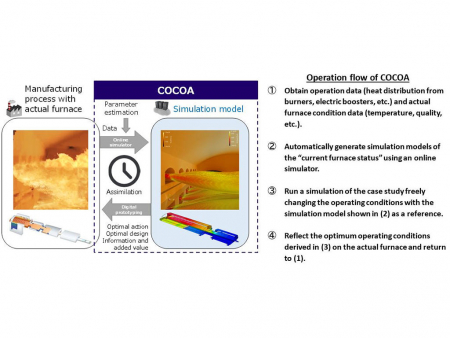

AGC has developed the CADTANK Online Computation and Optimization Assistant (COCOA) as a digital twin technology for the glass melting process that integrates an online simulator with a digital prototyping tool. Full-scale operational verification at AGC’s float furnaces is scheduled to begin in February 2023. This technology enables rapid and detailed understanding of the glass melting process and preliminary study of production conditions, which have been difficult to achieve in the past.

The temperature inside a float furnace and the flow of molten glass change daily depending on various factors such as the condition of the raw materials and refractories, which greatly impacts the quality of the glass produced. As these factors change, it becomes necessary to re-derive optimal operating conditions. To solve these issues, AGC developed the simulation tool COCOA, which can check changes in temperature distribution inside a furnace, the flow of molten glass, etc. from a simulation model automatically generated using float furnace operation data.

This enables process technicians to easily and directly conduct detailed condition assessments and preliminary studies of production conditions inside the glass melting process. In the future, AGC will build an efficient production system based on simulation forecasts and utilise this system to reduce GHG emissions.

AGC is working on automatically estimating information that is difficult to measure and necessary to run simulations, using a technique called “data assimilation”. Once this is achieved, the real-time forecasting accuracy of digital twin technology will be further improved and its use will be expanded.