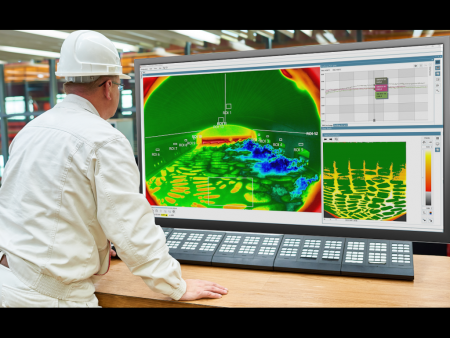

Measuring batch coverage and crown temperatures

AMETEK Land has added further features to its IMAGEPro software for use with the NIR-Borescope-2K Glass thermal imaging solution in glass melt tank applications.

The NIR-B-2K provides a thermal image with an outstanding definition of nearly three megapixels (1968 x 1472). It is not affected by the hot atmosphere or gases of the furnace and allows operators to measure from any of its three million fully radiometric-calibrated pixels, providing data to optimise furnace temperature.

Latest innovations to the IMAGEPro advanced thermal image processing software mean that the thermal imager can now measure batch coverage near the throat, as well as crown temperatures inside glass melt tanks, bringing further quality and operational efficiencies to producers.

Phillippe Kerbois, Glass Industry Manager for AMETEK Land, explains: “Now it is possible to monitor the batch coverage near the throat end of the melt tank, this helps to avoid large amounts of batch entering this area and potentially causing glass defects. This latest IMAGEPro-Glass software is an integral part of NIR-B-2K-Glass and is invaluable for any business wishing to optimise quality in their glass melt tanks. Importantly, it supports glass producers on their path to Industry 4.0, enabling increased automation and complex data exchange in glass manufacturing processes.”

Temperatures drop when batch moves to the front of the furnace. Within the IMAGEPro-Glass software, regions of interest can be used to set alarms for the furnace’s Distributed Control System (DCS) and facilitate better control of the batch coverage by adjusting the batch charging direction and length.

With the updates to IMAGEPro, key batch monitoring features include the ability to gain a top 2D view of the melter, set a region of interest in front of the throat, configure a batch ROI in the coverage melting grid and adjust the batch length manually. As variation in batch coverage directly impacts furnace temperatures, it must be carefully monitored.

The software has been designed for use with AMETEK Land’s NIR-B-2K thermal imaging solution. This is a short wavelength radiometric infrared borescope imaging camera, designed to produce high definition thermal images and provide accurate temperature measurements from any of the three million temperature points in the image.

The camera measures temperatures in the range 1000°C to 1800°C and is suitable for float glass, container glass, borosilicate glass and fibre glass melt furnaces.

Analysis areas within the NIR-B-2K image can be defined by the user and trended, showing maximum, minimum and average temperatures.

Operators can use the playback view to replay events and stop at any frame to measure multiple temperatures at the same point in time. This is particularly useful if measuring port arch temperatures at the moment of reversal.

AMETEK Land has recently introduced dedicated in-furnace thermal glass surveys to complement its range of equipment, which allow glass producers to gain insight to the thermal processes with accurate real-time temperature measurements.

The service comprises a site induction, pre-meeting, set-up and thermal survey from a specific number of furnace locations, with equipment rental and a final report included.

In partnership with Simpson Combustion and Energy Consultancy, combustion analysis can also be undertaken to offer additional advanced surveys.