DSF Announce Ownership Change

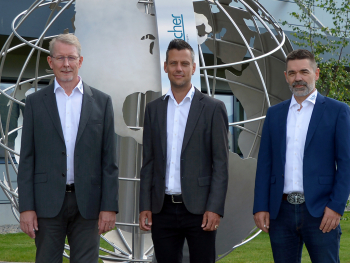

A management buyout of DSF took place on 19th December. The new ownership team, led by Paul Hutchinson, acquired the total shareholding of the group.

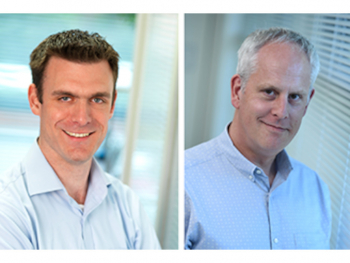

The main shareholders of DSF, Geoffrey Bell (Chairman) and Neale Parkin (Managing Director), have stepped down from their roles in the business following the acquisition of their shares. The company would like to place on record its thanks to Mr Bell and Mr Parkin for their many years of service and wish them the very best for the future.