OCMI brings out new index rotation forming machine for vials

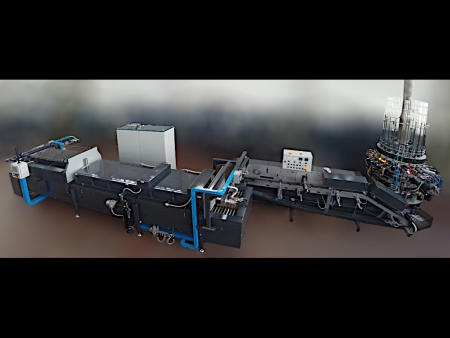

To meet market demand, particularly regarding hydrolytic resistance levels, OCMI Group has launched a completely new model of its index rotation forming machine for vials. The new machine has 18 upper and nine lower stations.

As a result of technological developments related to servo-controlled forming tools, OCMI’s FLA20/S vial forming machine is already penetrating growing Asian markets such as China and Pakistan.

With the range of production lines it owns, OCMI Group has full quality control from beginning to end of the process thanks to hot-end and cold-end camera inspection systems, both developed by OCMI Group engineering.

OCMI can now offer two alternative hot-end camera control systems for dimensional inspection operating on oxygen level and positioning/timing of pre-forming burners.

At the end of the line, a new cold-end inspection system with four cameras ahead of the packing station allows the user to perform printing control and to check the quality of rings, OPC (one point cut) point and cut and main ampoule dimensions.

OCMI Group has taken advantage of its recent renovation to add new options for automatic loading and packing operations.

View OCMI’s presentation in the Virtual Marketplace: www.glassworldwide.co.uk/virtual-marketplace. The full version of the above news has been published in the May/June issue that has been posted globally and is available to read free of charge in the Digital Archive (sponsored by FIC) at https://www.glassworldwide.co.uk/Digital-Issues