Precision ware handling at variable speeds

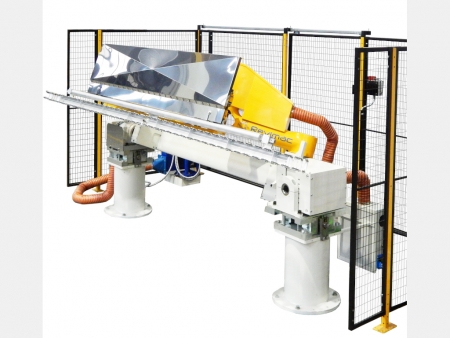

Based on a three axis design, Revimac’s RSS100 servo stacker is capable of operating at speeds of up to 22 cycles/min.

The three brushless servomotors allow users to operate an approaching, pursuit, loading and back cycle, always maintaining full control in each phase.

Via the user-friendly interface, it will be intuitive for personnel to customise curves and movement profiles to fit any type of glass container.

The push bar on the RSS servo stacker can be safely and quickly replaced thanks to a ‘bar change’ cycle that folds back the arms and rotates the main 90° beam, taking the bar into an easy position for maintenance.

In this way, the space in front of the annealing lehr is completely free, allowing cleaning and maintenance operations for cross conveyor and annealing lehr as well.

With its self-learning function, the stacker will automatically manage the loading profile with few inputs and phase the loading curve by detecting the speed of the IS machine.

The control cabinet contains a motion controller that is connected to an industrial PC, which functions as an HMI (15in).

The main characteristics of the operator interface are preview loading curve simulation and simplified management of the loading curve by setting four commands only (approach speed, pushing speed, start and end position). www.revimac.com

Pictured: Revimac’s RSS100 servo stacker.

Revimac is one of over 100 leading suppliers with a presentation in the Virtual Marketplace, Glass Worldwide’s digital showcase of the latest industry innovations: https://www.glassworldwide.co.uk/virtual-marketplace