Applied Vision intent on eliminating rotation and carousel machines

Understanding the cost and limitations rotary carousel machines place on manufacturers has been the key driver of Applied Vision Corporation’s mission to provide a non-contact, non-rotate empty glass container inspection.

The manufacturer of machine vision systems for the food and beverage industry is keen to reduce extra inspection legs necessary in cold end material handling, warehousing of container tooling, and complex and difficult job changes.

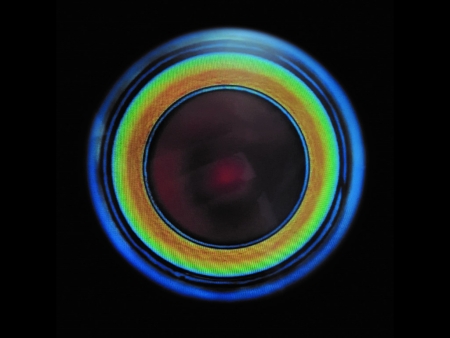

To this end, it has already replaced several traditional inspections requiring contact to inspect, or to rotate and inspect with its non-contact, non-rotate vision-based solutions. These include the company’s six camera vision dip and saddle, vision plug gauging and multi-view sealing surface and wire edge/overpress inspection modules – all of which are options in Applied Vision’s Volcano product range.

Currently in development at Applied Vision are two ‘industry game changers’: full profile glass container wall thickness inspection and non-contact, non-rotate check inspection. The company reports that these innovations ‘are showing real promise’. Its intention is that these two inspection types – along with existing technologies from Applied Vision – will eventually allow for the complete elimination of rotation and carousel machines.

The full version of the above news has been published in the May/June issue that has been posted globally and is available to read free of charge in the Digital Archive (sponsored by FIC) at https://www.glassworldwide.co.uk/Digital-Issues. For a digital showcase of the latest innovation from leading suppliers, visit the Virtual Marketplace at www.glassworldwide.co.uk/virtual-marketplace